- Home»

- Resources»

- Record Keeping and Benchmarking»

- Introduction to Record Keeping and Benchmarking

Introduction to Record Keeping and Benchmarking

Are you curious about which areas of your operation are excelling? Or which areas of your operation that might need some work?

Are you curious about which areas of your operation are excelling? Or which areas of your operation that might need some work?

Are you interested in record keeping but not sure where to start?

Successful farm management begins with accurate and up to date records. The process of record keeping allows the farm manager to collect and save data so it can be analyzed and used to make better decisions and turn information into actions1.

A good record keeping system helps take the guesswork out of management decisions. Farm managers who have high-quality records become more efficient and profitable; therefore, collecting good (i.e. complete, simple, appropriate and accurate) data is the key step to having the information you need to understand your farm performance better1.

It is important for producers to identify what information is needed to support you in making management decisions. While collecting, maintaining, and analyzing records requires an investment in time, the ability to make decisions based on a known history of your particular farm is valuable. One way to truly assess the impact of management decisions is to have production records pre and post changes. By comparing against your operation’s own history, you can identify the key factors that influence profit and concentrate on improving those areas3.

Why should I keep records?

|

Producers with 100 exposed cows that are keeping records can earn up to an estimated additional $13,200 per year |

- Evaluate past performance of the operation

- Provide a financial picture of the present situation

- Serve as a planning guide for future decisions

- Participate in quality assurance and premium marketing programs

- Improve on-farm profitability

- You can’t manage what you don’t measure

Benchmarking

|

Benchmarks such as calving rate, weaning rates and death loss can be used as a guideline to measure the performance of your operation. For example, the industry benchmark for calving rate is 94% live calves after each calving season. |

Benchmarking involves collecting data to generate production or performance averages for managers and producers to compare themselves against past performance or other producers in their area in order to identify strengths and weaknesses in their operation and to improve performance5.

Once you have recorded data for your own operation, you can use industry benchmarks as a guideline to determine how your operation is performing and then make accurate adjustments accordingly. By comparing and benchmarking against other operations, producers can identify gaps and learn from top performers3.

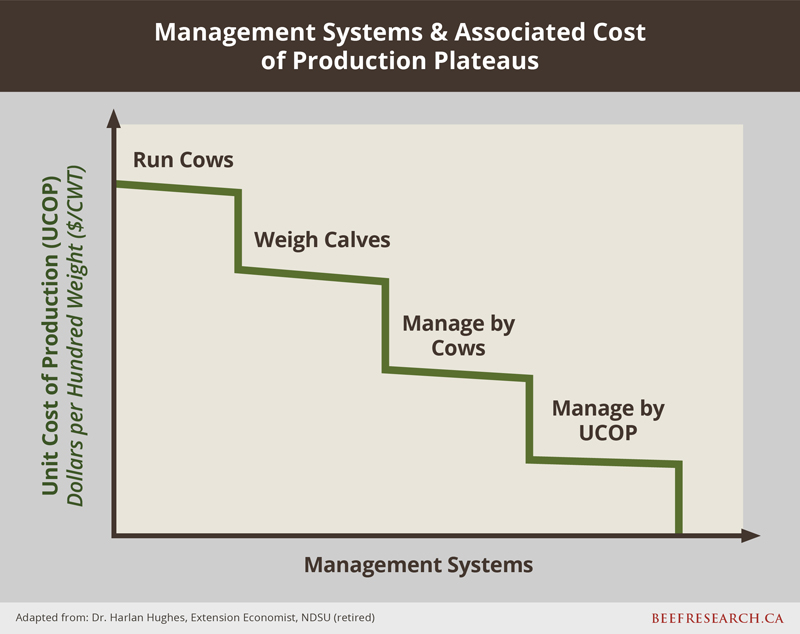

Dr. Harlan Hughes’ analysis of North Dakota cow/calf operations showed that those actively using their own farm data tended to have lower unit costs of production per lb of calf weaned (Figure 1). The operations that were using their own data were also the most profitable over time. The more information producers gather on their operations, the more efficient the knowledge and management of their herd becomes7.

Figure 1 – Management systems and associated cost of production plateaus.

Recent studies suggest that producers who keep records and use industry benchmarking have higher production with an average of up to 60 more lbs of calf weaned per cow exposed3. Assuming a herd with 100 exposed cows, this is equivalent to an additional 6,000 lbs weaned for the herd (+11%) valued at $13,200 per year in a high price environment (550 lb calf at $220/cwt), and $9,600 at long-term average prices ($160/cwt)1.

Setting goals for your operation6

From a management perspective, having goals is like following a road map - they help producers plan how to get to where they want to go. Keeping and analyzing records is important to accomplish a goal. One of most important purposes of goal setting is to improve performance as well as financial success6. Keeping records is a key tool to measure and track goal setting and business success.

- Start by thinking about your end result. If you don’t know where you’re going it will be very difficult to get there. Developing a plan will help identify where some of your stops or detours might be.

- Develop SMART Goals. SMART goals are Specific, Measurable, Attainable, Realistic and Time-based.

- Prioritize your goals. After you have developed a list of goals for your operation, prioritize them.

- Implement goals. In order to meet your goals, you have to put some time in planning out your goals. Take each goal and break it into smaller chunks that are easier to handle and set a timeline for completion.

- For example (Table 1), maybe one of the ways to achieve greater production is by improving your weaning weights. What can you do in the next six months to improve weights? Implement creep feeding? Improve grazing management? Mineral supplementation? Parasite control? Improve genetics? Improve water quality? The list goes on. Each of these tasks can be set to a timeline.

- Track your progress. If you have taken the time to map out your goals and to keep good records, you should be able to monitor how close you are to achieving your goals. From the example below in Table 1, we can see how progress towards increasing weaning weights may happen over the next five years.

Table 1: Setting a goal to increase weaning weights by 20 lbs by the year 2023.

|

Goal |

Date |

Progress |

What changed? |

Mitigating Factors |

|

Increase Avg WW by 20 lbs by 2023 |

Nov 2019 |

550 lbs |

Baseline |

|

|

Nov 2020 |

560 lbs |

New bull |

|

|

|

Nov 2021 |

545 lbs |

Creep feed |

Drought |

|

|

|

Nov 2022 |

565 lbs |

Creep feed + pasture rejuvenation with legumes |

|

|

Nov 2023 |

570 lbs |

Nothing |

|

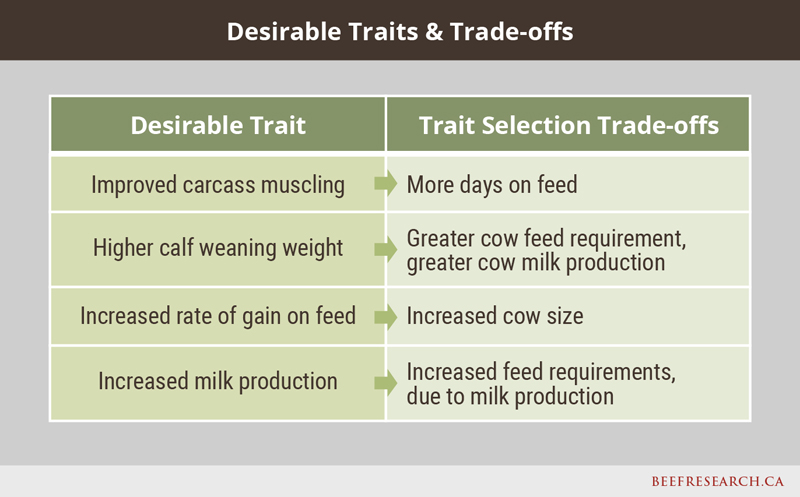

When making improvements to your production system it is good to also be aware of the potential for trade-offs from the changes that you are implementing. A trade-off is when you give up one thing in favour of another. These trade-offs may not always be a negative change, but they could impact your production or management practises. Examples of trade-offs can include7:

The following modules are designed to be used by a wide range of producers and management systems. Some operations may not fit perfectly into one level for all of the topics. For example, your financial record keeping may already be at the intermediate or advanced level, but you may feel that you are more of a beginner in the forage and grassland area. Each of the levels have been developed to target a level of experience where level 1 is a good starting point for beginners; level 2 is for someone that is more than a beginner but not quite advanced; and level 3 is designed to be the most advanced level. Your current record keeping practices may be a combination of levels depending on topic, which is normal and to be expected!

| Level | Animal Health and Performance | Forage and Grasslands | Genetics | Financial |

|---|---|---|---|---|

|

If you are just getting started with record keeping, this level is a good place to start. |

- GOLD Standards

|

- Range health

|

- Hybrid vigour while maintaining a uniform calf crop. | - Information needed for taxes and how to be organized. |

|

This level builds on the information collected in Level 1. |

- Mature cow weights - Body condition scores - Calving distribution - Cow-to-bull ratio - Calculating pounds of beef produced per cow exposed |

- Winter feed inventory and stored forages

|

- Using records to select replacement heifers and bulls

|

- Balance sheet - Income statement - Cash flow - Equity - Per unit cost of production |

|

This level builds on the information collected in levels 1 and 2. |

- Sorting calf/cow records based on management groups or individual identification - Calculating 205-day self adjusted weaning weights |

- Calculating carrying capacity and AUM

|

- Identifying bulls with better calf performance - Calving ease data - Weight data for EPD calculation

|

- Farm financial ratios

|

Feedback

Feedback and questions on the content of this page are welcome. Please e-mail us.