Extended Grazing

Methods to extend the grazing season, including stockpiled perennial forages, use of annual forages, crop residues, and bales left in the field, have considerable economic and environmental benefits over traditional winter-feeding systems. Well managed systems reduce or eliminate labour, harvesting, transport and delivery of feed, and manure handling. These systems also allow for flexibility in returning nutrients back to the land instead of concentrating animals in pens. However, the ability to implement a winter grazing system is dependent on a number of variables including water availability, snow conditions, provision of shelter, backup feed availability and forage use by wildlife.

On this page:

Key Points

|

Benefits of Extended Grazing

Numerous studies have demonstrated the economic and environmental benefits of extended grazing systems1. Costs of production are reduced compared to more traditional winter feeding in confinement, along with benefits to the environment and agronomic performance due to improved soil fertility and forage yields. Barriers for adoption expressed by producers include too much snow, too much ice buildup or snow crusting, lack of a winter water source, cold weather, feed waste, animal welfare and animal performance, all potential risks which must be carefully monitored and managed.

Numerous studies have demonstrated the economic and environmental benefits of extended grazing systems1. Costs of production are reduced compared to more traditional winter feeding in confinement, along with benefits to the environment and agronomic performance due to improved soil fertility and forage yields. Barriers for adoption expressed by producers include too much snow, too much ice buildup or snow crusting, lack of a winter water source, cold weather, feed waste, animal welfare and animal performance, all potential risks which must be carefully monitored and managed.

Potential economic benefits might be found in feed, labour, machinery, and residue and manure management costs. Extended grazing may reduce or eliminate the cost and time needed for harvesting forage and machinery use for handling feed. In systems where animals harvest their own feed, the associated labour and machinery costs will be lower. Extended grazing may also decrease the costs associated with corral cleaning and manure spreading.

Extended grazing also has environmental advantages. Manure is spread over the entire pasture or field, minimizing the potential negative effects of concentration in one area. Natural fertilization can occur over a managed land base at rates that are environmentally beneficial. Additionally, the reduction or elimination of machinery and equipment use results in less fuel and energy use.

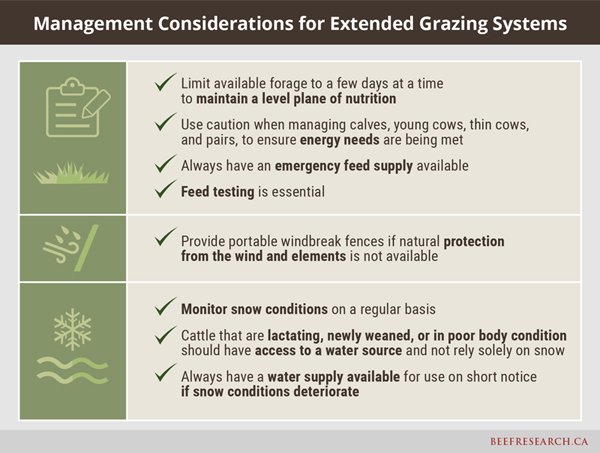

For any type of extended grazing system to be successful, good management is needed to keep cattle healthy and in good condition. Forage quality, fencing, water and shelter are important elements that need to be carefully planned for regional conditions.

Producers should carefully consider stocking density and environmental impacts when designing winter grazing strategies. There is a high risk of nutrient runoff during winter months, so care should be taken to limit the amount of manure deposited on a given piece of land by allocating sufficient land per animal. It is important to recognize that different provinces have different regulations surrounding manure management. Visit the Manure and Nutrient Management topic page for more information.

Be aware that livestock expend 18-20% more energy to harvest their own feed compared to animals being fed in a drylot system, mainly due to the extra energy needed to search for feed and to stay warm under winter grazing conditions. Strip grazing, using electric fencing, or moving cattle from field to field provides a more uniform nutrient intake and utilization per acre is greatest when fields are strip grazed versus whole-field grazed. When cattle are allowed to graze larger (whole-field) areas for longer periods of time they consume the best feed first. This may result in cows gaining weight early on followed by a declining plane of nutrition which can lead to significant weight loss after the best feed has been harvested or in the case of corn grazing, risk of acidosis due to overconsumption of high energy cobs. To keep cows gaining or maintaining weight without supplementing grazing resources, move them more often to fresh fields or strips to ensure adequate quality. Trampling and feed waste will also be reduced with managed grazing.

As with all winter management scenarios, producers should consider whether their extended grazing system will fit the class of cattle they are working with and the environmental conditions of their region. Caution is required when managing calves, young cows, thin cows and cows with calves, as they require higher levels of energy and management than mature dry cows. If grazing these higher energy demanding classes of animals during the late fall or winter, you may need to provide supplemental feed and shelter when conditions dictate. An emergency feed supply during severe winter weather will likely be necessary and should be available in the event conditions are not conducive to extended grazing in a particular winter. Feed test and adjust ration supplementation as needed during winter grazing. Remember protein and energy requirements for mature pregnant cows increase during the second and third trimester.

The Beef Research School video, Using a Feed Test to Maximize Profits and Avoid Pitfalls, outlines the importance of feed testing and discusses practical application within your operation.

Where possible, select a pasture or field with protection from the wind, and that is accessible on cold, windy days, during periods of large snow accumulation or periods when snow converts to ice. This will allow easy monitoring of animals, and if required, movement of animals to a better location. The pasture or field should have or allow the setup of a water system nearby if snow is unavailable or not adequate, and where access to forage is not limited due to severe snow drifting. If natural windbreaks are not present, man-made windbreaks are recommended and can include the use of portable windbreak fences or stacked bales with an electric fence barrier. Initial fields chosen for grazing should begin with fields furthest away from pens or more protected wintering locations. This will allow animals to be closer when weather conditions worsen as the seasons progress.

After a short adaptation period, non-lactating beef cows will consume snow in amounts equivalent to the intake of cows receiving water and can meet their water requirements as long as the snow is adequate in quality and quantity; snow must be clean, loose, non-crusted and deep enough to cover the ground. Snow must NOT be used as the sole water source for cattle that are lactating, newly weaned, have a body condition score of less than 2.5 out of 5, or don't have access to optimal feed resources2. Changing weather conditions can cause snow to disappear quickly and the quality of snow as a water source will deteriorate due to blowing wind, thaw, refreezing and crusting. Producers need to check snow conditions regularly. If in doubt, provide cattle with access to fresh water which means always having a water source available on short notice.

Due to the nature of frequent freeze-thaw cycles in Eastern Canada, it is highly recommended to provide a source of water, outside of snowfall, when extended grazing to ensure access to a critical resource for animals. Caution should be used when using a pond, dugout, or other deep-water source. These areas should be fenced to limit the ability for cattle to walk out onto the ice as this could lead to them falling into the water and drowning.

The biggest stress for cattle eating snow is during the transition period. Cattle that have not eaten snow and have only consumed water will often vocalize to show discontent. After a day or two, the herd learns from those that are early adapters.

Cows can graze through significant amounts of soft snow, however, wind-swept or severely crusted snow makes grazing difficult or impossible. Periods of freeze-thaw cycles will result in thick crusts of snow or ice. If the snow is too hard or crystallized, the animal's nose becomes tender and lower leg hair can be rubbed off. If the snow becomes too hard or too deep, it may be physically impossible for the herd to access forage. A BCRC Blog post looks at the question, Is It OK to Use Snow as the Only Water Source for Cattle?

Always have a ‘Plan B’ or back-up options to implement on short notice when using extended grazing systems. This includes having stored feed on hand, access to a water source, and pens or shelter that cattle can be moved to in the event that severe or inclement weather is imminent or extended, making grazing impossible or harmful to animals’ welfare. A late spring can also mean that planned grazing resources run out too soon and stored feed must be available. Producers must also pay attention to field conditions during freeze-thaw cycles in the winter and early spring as, depending on the field site, animals may damage fields during these periods and/or may become covered in mud, which will impact their ability to stay warm.

The following video from Alberta Agriculture and Forestry, titled Winter Grazing Systems: Dealing with Extreme Cold and Snow, provides producer tips for winter grazing.

The below webinar hosted by VBP+ and the Maritime Beef Council presented management considerations for winter grazing and feeding in regions across eastern and western Canada including:

Nova Scotia - John Duynisveld (9:05)

Quebec - Bernard Doré (21:28)

Alberta - Sean McGrath (39:11).

Visit the BCRC Blog post, Tips for Successful Extended Grazing to Reduce Winter Feeding Costs, for a summary of practical animal management considerations including body condition, water, feed testing, shelter, control of grazing, animal monitoring, and having a contingency plan.

Considerations When Choosing an Extended Grazing System

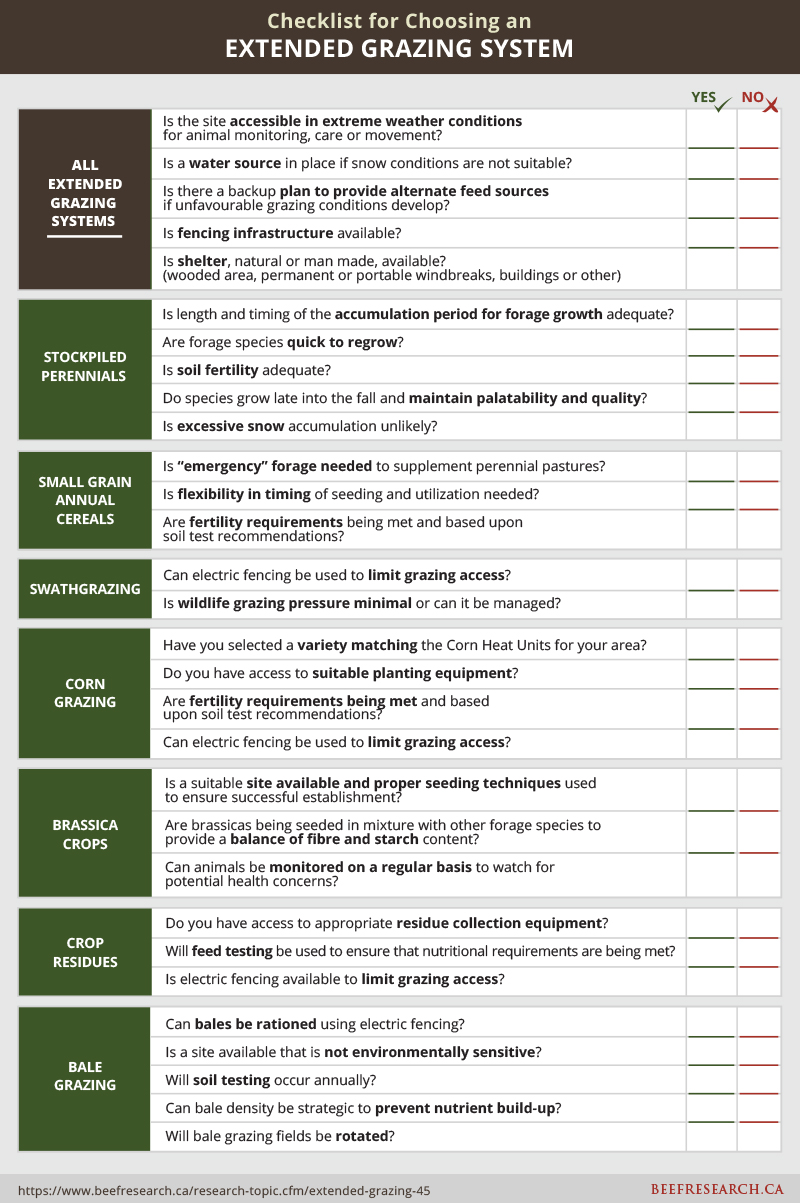

When considering implementing an extended grazing system, it is important to evaluate the resources available as well as the management practices you are willing and able to employ.

It is possible to use multiple methods to achieve production goals. And not all systems are recommended for all regions due to the timing of rainfall, amount of rainfall and snowfall, and type of snowfall (wet or dry snowfall or mixed snow and rain). For example, swathgrazing is not recommended in many regions of Central and Eastern Canada due to high precipitation. On the western coast of Newfoundland extended grazing plans may quickly be disrupted by large snowfall accumulation.

The following questions are not all-inclusive but do highlight critical topics to assess.

Stockpiled Perennials

Stockpiled perennials include pastures or hay fields that are saved for fall, winter, or early spring grazing after forage growth has stopped. Stockpiled pasture may also be referred to as deferred or dormant season grazing.

Stockpiled perennials include pastures or hay fields that are saved for fall, winter, or early spring grazing after forage growth has stopped. Stockpiled pasture may also be referred to as deferred or dormant season grazing.

To achieve adequate forage yield for dormant season grazing, it is essential to plan well in advance of the growing season to allow for adequate time for growth and forage accumulation before the growing season ends. Forage stands must be given enough time to recover and regrow following grazing or cutting to make subsequent stockpiled grazing successful. Remember that livestock must be removed from the pasture during the growing season to allow enough time for the stand to regrow before plants go dormant.

Timing of the accumulation period is also critical in achieving the appropriate quality and quantity of reserved forage. If forage quality is most important, plant material should be less mature when dormancy occurs, however, forage yield will be sacrificed. When quantity is the main goal, a longer regrowth period will result in greater yields of more mature forage, but at the expense of quality.

Remember that the emphasis placed on yield versus quality must always be aligned with the type of animals to be grazed. Dry cows will have lower nutrient requirements and can utilize lower quality feed better than cow-calf pairs, weaned calves or yearlings. It is possible to use different pasture management decisions on different fields to have a mix of yield and quality of stockpiled forages depending on feed needs and class of cattle for different times of year 3.

At New Liskeard, Ontario, pasture that was rested beginning in mid-July had a fall (October/November) yield of 4500 kg/ha (4050 lb/acre) while similar pasture stockpiled after mid-August had a fall yield of 2600 kg/ha (2430 lb/acre)4. The earlier summer starting resting date resulted in lower pasture quality in the fall compared to a later resting start date. Pasture rested in mid-July reported 10.3% crude protein and 58.5% TDN (total digestible nutrients) in the fall, while the pasture rested beginning in mid-August tested 14.7% crude protein and 63.4% TDN in the fall.

Faster regrowing species will provide more biomass for grazing than those species that regrow more slowly. Adequate soil fertility enhances regrowth of the stand and extends the grazing time into the fall and winter. Nitrogen may be applied at the beginning of stockpiling to increase yield by time of grazing, however whether this is cost effective will depend on forage replacement and fertilizer costs in a given year 5. A study completed in New Liskeard, Ontario from 1995-1997 found that an application of 50 kg/ha of actual N (as 34-0-0) applied at the beginning of stockpiling significantly increased yield compared to a pasture without the nitrogen application in 1996 and 1997 but not in 1995. The average yield increase across the three years was 750 kg/ha by the time of grazing.

Species must also be selected for their ability to grow late into the fall for maximum palatability and quality, and for their ability to remain physically accessible to animals once dormant. Species that shatter or have significant leaf loss once dormant, such as alfalfa, are not well suited to stockpiled grazing. Some species maintain nutritional quality better than others. Russian wildrye, tall fescue, meadow bromegrass, cicer milkvetch and some native grasses, such as Western wheatgrass6, maintain their quality relatively well through the dormant season. Fescues, in particular, are a good choice for areas with significant freeze-thaw periods.

Work conducted by researchers at the University of Manitoba to evaluate annual and perennial forages for stockpiled grazing included an examination of the impact of forage quality in fall/winter grazing systems on animal performance, grazing behaviour, feed intake and energetic efficiency.

It is important to ensure that stockpiled forage is able to adequately meet animal nutritional requirements. Forage value declines due to weathering losses and this has significant implications for grazing7. Decomposition of the plant material reduces both the amount and quality of forage available for grazing and therefore reduces grazing efficiency. Be sure to feed test stockpiled forage to determine the protein and energy status during the dormant season to determine whether supplementation is required or not.

If there is adequate quantity and quality of stockpiled forage, cattle will graze through 15 centimetres (6 inches) or more of soft, loose snow. However, cattle may have difficulty accessing forage if there is a significant surface crust. Controlled grazing systems using an electric fence is recommended when snow cover is present. Livestock can then be limited to two to three days of forage supply at one time which allows for improved management of feed utilization and reduced wastage. A backup fence is recommended in case ice accumulation on poly wire affects the integrity of the fence system.

Research conducted in western Canada comparing grazing of stockpiled perennial forages with drylot feeding round bale hay showed that averaged over three years, total system costs were 14% less for stockpiled grazing8. Management strategies included supplementing forage supply when needed to maintain body weight and body condition score. Results suggest that stockpiled grazing perennial forages can be a viable strategy without any negative effects on beef cow performance.

Grazing Annuals

Small Grain Cereals

Annual cereals can be grown to produce pasture in the same year that it is needed with forage available for grazing approximately six to eight weeks after seeding9. Spring or winter cereals can supplement perennial pasture, increasing the overall forage supply and providing flexibility depending on timing of seeding and subsequent utilization. They are often used when emergency sources of forage are needed such as during drought conditions.

Preferred cereals to grow for grazing are often fall rye, winter wheat and winter triticale as they can be fall seeded and fall grazed or overwintered and grazed in the spring. Winter cereals may also be seeded in the spring and used in the summer.

Oats, barley and spring triticale are also common as a forage source. Forage yield of oats and barley are generally equal with triticale usually yielding lower9. At the same stage of maturity, forage quality is similar for all three of these spring cereals.

Corn is also becoming a more common forage source used to extend the grazing season (see the Corn Grazing section below to learn more).

Rye grasses are another option for extending the grazing season as they grow late into the fall and provide growth when all other forages have become dormant. They do not overwinter and act as an annual under Canadian conditions.

Plant breeding work to evaluate annual cereals for forage characteristics is an ongoing effort. Examples of results being generated can be seen in the research project factsheets Improved Forage Oats and Breeding Forage Wheat.

Swathgrazing

For swathgrazing, spring seeded cereals, winter annuals, annual legumes or combinations of these are cut in the fall for cattle to graze during the winter. Swathing is done late enough in the fall so that cool daytime temperatures prevent mold growth. Swaths should lay on top of the stubble and be as narrow and deep as possible.

For swathgrazing, spring seeded cereals, winter annuals, annual legumes or combinations of these are cut in the fall for cattle to graze during the winter. Swathing is done late enough in the fall so that cool daytime temperatures prevent mold growth. Swaths should lay on top of the stubble and be as narrow and deep as possible.

Annuals such as late-maturing barley or oat crops are typically used for swath grazing due to their relatively high yield. Studies have shown that corn and triticale are also good options for winter swath grazing.

Seeding should be timed to ensure that crops are swathed just before the first killing frost in order to maximize yield and achieve the desired stage of maturity. While traditional recommendations have been to swath crops between the late milk and soft dough stages, recent research findings suggest that cutting at a later stage of maturity has advantages10. Oat, barley, and triticale swathed at the hard dough stage resulted in increased available biomass and nutritive value with all three crops at protein levels suitable for mid-gestation beef cows. With increased crop yields, grazing days will also be increased resulting in reduced winter grazing costs. Ongoing research will further refine recommendations for optimum time of harvest of annual cereals for swathgrazing.

Electric fencing should be used to control forage utilization. Cattle should be allocated enough swath so that they clean up the area in about two to three days. If access is not managed, there is greater chance of swaths being trampled, mixing snow with the forage. This then may cause freezing of the forage, making it difficult to reach or inaccessible for grazing. In addition to minimizing waste, limiting available forage to a few days at a time also ensures a more level plane of nutrition by preventing selection of a high proportion of heads initially followed by poorer quality feed that remains including straw and residue. This is especially important with higher energy feed sources, including corn grazing, as grazing animals will preferentially select cobs which, due to their high energy content, can lead to acidosis and death. A backup wire should be used in areas that receive heavy snow or freezing rain. An accumulation of ice on poly wires can weigh it down sufficiently that cattle can escape and access more of the field. An extra poly wire increases the chances that cattle will remain in the allocated grazing area.

|

Cattle should be allocated enough swath so that they clean up the area in about two to three days. Limiting available forage to a few days at a time also ensures a more level plane of nutrition and reduces the risk of acidosis. |

To open up areas in times of heavy snow a tractor may be driven down the swath or a blade used to move snow off the swath. Often, simply exposing the end of the swath will attract cows and they will then follow and graze down the length of swath provided. In the case of crusting, cattle may need to be shown where the swath is by breaking the ice crust. Depending on ice thickness cattle may use their hooves to break through to the swath on their own. Placing electric wire fencing across the swaths helps to expose the ends of the swath which enables cows to see the continuation of the swath after each fence move. Another concern is the freeze-thaw cycle after a swath has become frozen and inaccessible. Warming temperatures may result in damage to the swath, leading to rot and waste.

For all types of extended grazing, including swathgrazing, it is essential that body condition be monitored very closely on a regular basis. Swathgrazing increases the animal’s energy requirements by approximately 18-20% so, depending on the feed source and environmental conditions, which can be very unpredictable, cows can lose condition quickly if not being watched closely. The Beef Research School video, The Benefits of Swathgrazing, provides an excellent overview of management aspects of this extended grazing strategy including the advantages of swathgrazing cattle (0:16), teaching animals to swathgraze (1:02), selecting a suitable site (2:25), benefits (4:48), and allocation of swaths (5:49).

Depending on weather and management practices, feed usage from swathgrazing can be as high as or higher than the usage of harvested hay or silage crops. Allowing livestock to obtain all or part of their feed through swath grazing extends the grazing season and reduces winter feed costs. Research indicates that swath grazing can reduce total daily feeding cost per cow by 41 to 48% compared to drylot feeding. This is based on a 78% reduction in yardage costs and a 25% reduction in feed costs. Daily feed costs for swathgrazing range from $0.61 to $1.80 per cow, largely due to variability in the number of grazing days per acre.

While well-managed swathgrazing has known economic benefits for producers, research results have shown that it can have environmental benefits as well. The BCRC Blog post, Another Look at the Costs and Benefits of Swath Grazing, summarizes a research project conducted at Agriculture and Agri-Food Canada’s Lacombe Research Station showing that extended winter grazing generates measurable reductions in greenhouse gas emissions as compared to traditional confined feeding.

Corn Grazing

Grazing standing corn is another option being used by producers to extend the grazing season, supplement perennial pasture, and increase overall carrying capacity. It is however, a relatively high input, high risk crop.

Grazing standing corn is another option being used by producers to extend the grazing season, supplement perennial pasture, and increase overall carrying capacity. It is however, a relatively high input, high risk crop.

Planting early maturing silage type corn varieties for use in late season grazing has tremendous potential as productivity is very high and the upright nature of the plant allows cattle to harvest the stand when the snow gets deep. The successful production of corn is highly dependent on the availability of cold tolerant varieties, adequate heat units, fertility and weed control. All four aspects are critical for successful production.

Select a variety that will match the Corn Heat Units (CHU) rating for your area to increase the chances of a high yielding and high-quality corn crop. The CHU rating indicates how many heat units are required for the grain to reach maturity. Low heat unit varieties (less than 2100 CHU) have been developed in recent years. On average, 200 fewer CHUs are required for corn to reach a moisture level and maturity level considered favourable for grazing or silage production as compared to grain production11. Corn Heat Unit maps are available on agriculture department websites in most provinces.

Grazing corn can be seeded with an air seeder, air drill, row planter or conventional hoe drill11. Work in Saskatchewan at the Western Beef Development Centre showed an advantage to using a precision corn planter, when possible, to maximize biomass production. From Manitoba to British Columbia, the recommended seeding depth is 1.5-2 inches deep, preferably into moisture, at a soil temperature of at least 10 degrees Celsius to germinate. From Ontario to Prince Edward Island, recommended seeding depth is into moisture, from 1.5-3 inches deep. Row spacing of 30 inches is recommended.

Corn has a relatively high fertility requirement. Fertilizer application, whether inorganic or manure, should be based upon local soil test recommendations. This crop does not compete well with weeds or volunteer crops so attention to weed control in early growth stages is critical.

A recent BCRC Blog post provides practical tips for planting corn including an overview of site and variety selection, seeding equipment, weed control, and fertility.

In years of heavy snowfall, cattle may have better access to standing corn compared to swathed crops under snow. Observations have also shown standing corn providing protection from the wind during inclement weather. Strip grazing, using electric fence, provides a more uniform nutrient intake, reducing the risk of acidosis caused by cattle only eating high energy cobs, and utilization per acre is improved. This also reduces trampling and wastage.

Research studies suggest that new cool-season corn hybrids can produce high quality forage to meet the nutrient requirements of grazing beef cows in mid- and late-stage pregnancy, providing a suitable alternative for winter grazing strategies with forage harvest costs eliminated12,13.

The BCRC Blog post, 5 Tips for Grazing Corn this Fall and Winter covers topics to help make the most of corn grazing including the importance of:

- allowing cattle time to slowly transition to this new feed source,

- limiting access to three to four days of feed at a time in order to manage risk of acidosis due to overconsumption of cobs,

- protecting cattle from the elements,

- feed testing, and

- having a back-up plan.

For more tips on grazing corn plus an excellent overview of considerations when using extended grazing systems, view the BCRC webinar, Refining Corn Grazing Recommendations, presented by Dr. Bart Lardner. Highlights include understanding Corn Heat Units (22:48), agronomics of growing corn (23:55), grazing management (30:35), and research results (33:00).

The Western Beef Development Centre video, Winter Grazing Standing Corn with Beef Cows, provides a virtual tour of a grazing corn system for beef cows featuring an overview of average input costs (1:55), and cow performance (2:30) including grazing days obtained and winter-feeding costs per day. In the project highlighted in this video, total crop input costs were in the range of $200/acre with yields of 4-5 ton/acre, resulting in a range of 150-300 cow days/acre and total feed costs of $0.70-$1.40/head/day. It is important to note that these values are specific to the varieties grown in the study, location variables, and management considerations.

The economics of growing corn will vary, and it is important, as with all management systems, to determine expenses and revenue projections for your own individual scenario.

Brassica Crops

Annual forage brassica crops can provide fast-growing, high yielding, quality late fall pasture. Brassicas being used by some producers to extend the grazing season include kale, forage rape, radish, turnip, and rutabaga. These annuals have been used in Europe as livestock forage for at least 600 years. Factors that will impact choice of brassica crops to use are the timing of planting, desired grazing period, and which class of livestock will be turned out onto the field.

Brassicas tolerate temperatures as low as -5 degrees Celsius and are well adapted to the cool, northern parts of Canada. Forage brassicas grow best on well drained soils with a pH of between 5.3 and 6.8 (moderately to slightly acidic). Typically, the crude protein content of kale and rape leaves ranges from 18 to 25 per cent and that of turnip roots from 9 to 10 per cent.

Brassicas tolerate temperatures as low as -5 degrees Celsius and are well adapted to the cool, northern parts of Canada. Forage brassicas grow best on well drained soils with a pH of between 5.3 and 6.8 (moderately to slightly acidic). Typically, the crude protein content of kale and rape leaves ranges from 18 to 25 per cent and that of turnip roots from 9 to 10 per cent.

Turnips have bushy tops and large roots that are rich in carbohydrates. Many varieties can be grazed twice, once for top growth (near the end of summer) and then later for the roots. Turnip has a lower dry matter yield than rape or kale. Although not common and dependent on a specific size and shape, there is the risk of animals choking on turnip roots, therefore, regular monitoring is advised.

Forage-type kale has very digestible leaves and stems and grows up to 5 feet (1.5 metres) tall under cool, moist conditions. Dry matter yields of kale range from 4,500 to 7,100 lb/ac (5000 to 8000 kg/ha) and grazing can begin in late summer.

There are two kinds of forage rape, a giant type which is leafy and upright and a dwarf type which is short and branched. The giant types of rape have higher yields and are more palatable than the dwarf ones. Rape is usually ready to graze about eight weeks after establishment. Note that forage rape is not the same as oilseed rape or canola.

Forage brassicas should be established in the same manner as canola. Ensure that the seedbed is firm and do not seed deeper than 0.5 inches (1.5 cm) or alternatively, seed with a zero-till drill into pastures or grain stubble. Seeding rates can be as high as 4.5 lb/acre (5 kg/ha) if a problem with weeds is anticipated. Seeding kales and turnips later than mid-June usually results in decreased yields. Later seeding dates for rape ensures that adequate forage is available in September. Moderate levels of potassium and phosphorus are required and about 18 lb/acre (20 kg/ha) of sulphur is essential for productive growth. Under irrigation, adequate amounts of naturally occurring sulphur should be available in the water.

Mineral supplementation provided for animals should ensure that the calcium-to-phosphorus ratio in the feed does not exceed 7:1. Forage brassicas are typically planted in a mixture with 50 per cent or more of the forage comprised of other species including cereals such as oats, barley, triticale or fall rye. This combination provides high digestibility and crude protein from the forage brassicas along with higher fibre and starch content from the cereals.

Brassica crops can cause animal health concerns if not managed properly. These forage types contain a number of inhibitory compounds that can interfere with thyroid function or cause anemia. Others potential issues include bloat, atypical pneumonia, nitrate poisoning, and hypothyroidism. Sulphur toxicity can occur, especially if the water source is also high in sulphur. These risks can be avoided by introducing animals slowly, over three to four days, to Brassica pastures or supplementing with hay or other grass pastures if continually grazing these crops14.

More information on the use of Brassica crops, including in mixture with other forage species, can be found on the Cover Crops page. A recent BCRC webinar, Integrating Cover Crops, includes an in-depth look at the use of complex mixtures including specific information related to nutrition considerations when grazing Brassicas (33:24).

Crop Residues

Crop residues of chaff and straw from cereal, pulse and oilseed crops can also be grazed in the field. Chaff consists of glumes, hulls, unthreshed heads, short straw, leaf material, weed seeds and whole or cracked kernels. Nutritive value varies depending on the crop type, stage of maturity at harvest, efficiency of harvest equipment, and the resulting relative amount of each component.

On conventional combines where the chaff exits the combine in a separate stream, the chaff alone can be bunched and collected. On rotary combines, the chaff and straw exit the combine in a single stream. Crop residue collection systems which collect and bunch either the chaff only, or the chaff and straw together, are used to gather and make piles in the field. Systems are available commercially or some producers choose to build a chaff box.

Grain in the chaff increases the feed quality. If there are a large number of small kernels in the sample, the combine can be set to throw the light kernels over to the chaff. Higher cutting heights when direct combining can produce feed with higher nutritive values than when cut at ground level. Although this approach reduces total straw yield, it improves the overall quality of the feed.

As with all grazing and feeding systems, feed testing is critical to evaluate quality and match animal requirements with nutrients being supplied. Environmental conditions, including snow depth and temperature, dictate forage availability therefore adequate supplementation may be necessary to ensure nutritional needs are being met15. For example, protein supplements are recommended when chaff contains less than 6 per cent crude protein to enhance the digestion of low-quality roughage.

Anecdotal reports suggest that new technology in combines has resulted in a reduction in the nutritional value of crop residues as more efficient machines separate out more of the higher quality components. This emphasizes the importance of monitoring feed quality and re-evaluating the practice if necessary.

As with other extended grazing systems, electric fencing is a valuable tool to control forage utilization and manage the quality of feed available to the animal. Limiting available forage to a few days at a time ensures a more level plane of nutrition by preventing sorting and selection of the highest quality components, leaving the lower quality straw until later in the season when nutrient demand may be higher.

Field grazing crop residue during fall and winter can reduce feed and yardage expenses. The costs associated with field grazing include combine attachments for bunching, electric fencing, wind protection, water provision and supplemental feed. Just as with other extended grazing systems, field grazing crop residues has environmental benefits as higher levels of nitrogen are recycled back to the soil through the deposit of manure and urine as compared to feeding in confinement.

Bale Grazing

Bale grazing is the practice of allowing livestock to graze bales on pastures and hayfields, rather than feeding intensively in confinement. Bales can be grazed where they are ejected from the baler or they can be moved to feeding fields, eliminating the need to stack and move bales to animals again in the winter.

Bales are rationed out to the cows throughout the winter by moving an electric fence periodically. Feed wastage is affected by the length of feeding period and quality of feed. Longer feeding periods tend to have greater waste as compared to the recommended range of two to five days.

Manure and left-over feed are distributed directly on the pasture or hayfield eliminating the costs of manure hauling. Low fertility areas of a seeded pasture or hayfield can be improved as added nutrients from the manure and feed not eaten will increase forage production in subsequent years. Several research projects in western Canada have reported higher forage production as a result of bale grazing. Over a two-year period at sites in Alberta, bale grazing consistently produced higher forage dry matter yield than a control site with no bale grazing16 with 100% higher forage dry matter yield at one site and 219% higher at a second site. Research in Saskatchewan compared winter feeding on pasture (bale grazing and bale processing) to conventional feeding in a drylot pen17. In this study, forage dry matter yields were 3.3-4.7 times greater where cattle were wintered on pasture as compared to control sites with no wintering of cattle. The higher forage production could be associated with improved soil physical conditions (infiltration rate, soil moisture and compaction) and soil nutrients (N, P and K in particular).

Bale grazing imports nutrients contained in the feed to a concentrated area plus also adds nutrients from urine and manure. These added nutrients increase the fertility of the area but can lead to localized areas of excess nutrient accumulation in the soil. Management needs to focus on preventing localized “hot spots” of nutrient accumulation to avoid environmental risk. This includes proper site selection, bale density, movement of cattle to ensure more uniform distribution of manure and urine, annual soil testing, and rotation of fields used for feeding.

The best option for bale placement is on seeded perennial fields. Avoid bale grazing on environmentally sensitive locations such as in riparian areas, sites where runoff will flow directly into surface water, on high water tables, or on sandy soil. Do not bale graze on native rangeland to prevent introduction of invasive and weedy species or altering the plant composition away from native species. On sites that are bale grazed, be prepared to address weed problems like Canada thistle or quackgrass that may develop on the heavily manured spots.

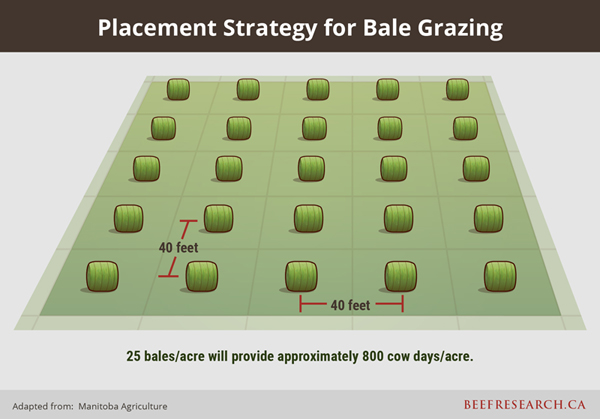

To avoid excessive nutrient build-up, a maximum density of approximately 800 cow days/acre is recommended which, depending on individual bale weight, works out to about 25 bales/acre. Recommendations for spacing of bales are dependent on a number of factors however a grid of 40-foot centers, leaving 30-35 feet between bales will allow ease of animal movement and relatively uniform manure nutrient coverage18.

In drier climates like Western Canada, place bales with plastic twine on their ends so that twine can be removed in the fall before feeding. Removal of twine or net wrap is important to prevent animals from ingesting material resulting in possible compaction and death. If using sisal twine, bales can be placed on their sides as the twine will rot. In more moist climates like Eastern Canada, bales should be placed on their sides to prevent moisture being wicked up the core of the bale and freezing. Twine should be removed in advance.

Annual soil testing allows for monitoring of nutrient status of bale grazing sites to prevent excessive nutrient build-up. Site selection and rotation of bale grazing fields should be based upon this information. General recommendations include not placing bales on the same grid as in previous years and rotating fields so that bale grazing occurs on any given site no more than every fifth year.

Bale grazing reduces yardage costs especially when bales are grazed in the hayfield where they were made. Costs increase the further the bales are transported to the feeding area and with the number of times they are handled. Be sure to do a cost analysis for your operation when considering this type of feeding system. An economic analysis using cost of production data from Atlantic Canada and Western Canada assessed the potential savings of using stockpiled grazing in combination with bale grazing in Atlantic Canada climatic conditions. The study found that producers may find a reduction of up to 54% of total annual production cost for feed, yardage, and straw bedding compared to a conventional feeding plan19.

The BCRC Blog, 3 Tips for Swath and Bale Grazing, summarizes some key considerations including matching the animal to the forage, leaving extra biomass on the field to help reduce problems with mud, and encouraging cattle to use as much feed as possible. This information is a summary of the following webinar presented by Dr. Vern Baron and John Duynisveld which provides a practical overview of swath and bale grazing strategies including how different crops and varieties rank in terms of yield.

Adoption of Extended Grazing Practices

The 2016 Census of Agriculture reports that 35.4% of Canadian beef cattle farms use in-field winter grazing or feeding. Adoption rates vary by region, largely due to climatic conditions, with these types of wintering management systems most popular in British Columbia (49%), Alberta (45.8%), and Saskatchewan (40%). Lower adoption rates exist in Manitoba at 30.7%, central Canada at approximately 20%, and Atlantic provinces at 15.9%1.

Between 2006 and 2011, a shift occurred on Western Canadian beef operations away from feeding animals in confinement during the winter months to wintering in fields or on pastures with feed provided by bales, stockpiled forage, or swath grazing. The 2016 Census of Agriculture reported that in-field feeding increased in Ontario, Quebec, and British Columbia between 2011 and 2016 but declined in the Prairie provinces. This reduction in the use of in-field winter feeding in some regions is not necessarily bad but does lead to questions as to why some producers have moved away from these systems. Is nutrition lacking, are there concerns about wasted feed, are wildlife a concern, or are there gaps in implementing winter feeding programs that result in higher costs rather than reducing costs as intended? Better understanding of these factors can help inform future research and extension efforts.

Acknowledgements

Updates to this page were completed in collaboration and with the expertise of staff at Perennia Food and Agriculture.

This topic was last revised on March 22, 2022 at 1:43 AM.

View Web Page

View Web Page View PDF

View PDF