Manure & Nutrient Management

Efficient and environmentally responsible use of livestock manure provides a valuable source of nutrients, organic matter and carbon to pastures and cropland. As a low input by-product, manure offers a long-term source of nutrients that can influence soil properties, increase soil carbon and nitrogen, and alter soil phosphorus and potassium concentrations along with other nutrients. Best management practices must encompass economic, social and environmental sustainability across all sectors from cow/calf to backgrounders and feedlots.

Efficient and environmentally responsible use of livestock manure provides a valuable source of nutrients, organic matter and carbon to pastures and cropland. As a low input by-product, manure offers a long-term source of nutrients that can influence soil properties, increase soil carbon and nitrogen, and alter soil phosphorus and potassium concentrations along with other nutrients. Best management practices must encompass economic, social and environmental sustainability across all sectors from cow/calf to backgrounders and feedlots.

On this page:

Key Nutrients in Manure

Cattle manure is a valuable source of key nutrients including nitrogen (N), phosphorus (P), potassium (K) sulphur (S) magnesium (Mg), and calcium (Ca) as well as certain micronutrients. Adding manure to soil impacts the chemical, biological and physical aspects of soil quality. Manure increases plant productivity, soil organic matter and structure, water infiltration and holding capacity, and over time, can reduce sediment loss and erosion with application and incorporation into soils. Composted manure can improve enzyme activity and bacterial diversity in soils1.

All plants, including grasses, legumes, pulses, cereals and oilseeds benefit from optimal levels of key nutrients. Each field and crop will have very different nutritional requirements. Conducting soil tests of the field or pasture will indicate current soil nutrient levels and potential deficiencies/surpluses. With commercial fertilizer blends, the ratio of nutrients is customized based on soil tests and target yields for the crop. With manure fertilization, customizing is not possible, and the nutrient level may not match the nutrient requirements. The amounts of N, P, K, S, Mg, Ca and micronutrients will typically vary widely between samples.

All plants, including grasses, legumes, pulses, cereals and oilseeds benefit from optimal levels of key nutrients. Each field and crop will have very different nutritional requirements. Conducting soil tests of the field or pasture will indicate current soil nutrient levels and potential deficiencies/surpluses. With commercial fertilizer blends, the ratio of nutrients is customized based on soil tests and target yields for the crop. With manure fertilization, customizing is not possible, and the nutrient level may not match the nutrient requirements. The amounts of N, P, K, S, Mg, Ca and micronutrients will typically vary widely between samples.

While the soil enhancing benefits of manure are recognized, few beef cattle producers send manure samples for analysis. The 2017 Farm Management Survey found that less than 15% of Canadian producers polled sampled manure prior to application on field crops, and less than 10% tested solid manure before application to pastures2.

|

Liquid and solid manure can be sent to several laboratories across Canada for analysis. Contact your provincial ministry of agriculture for a listing of available laboratories. |

Knowing the nutrient levels within the manure sample and understanding how the key nutrients impact pasture and crop growth will help with manure management.

Nitrogen (N) is a major component of chlorophyll and amino acids, which build proteins that are critical to plant life. Without proteins, plants wither and die. Some proteins are structural units in cell walls and some act as enzymes enabling biochemical reactions. N is also a component of nucleic acids like DNA which allows cells to grow and reproduce. Nitrogen is essential for plants to achieve optimum yields and directly impacts the protein levels in plants. Livestock require feedstuffs with adequate protein levels for growth, lactation, reproduction, and maintenance. Forage and pasture growth are highly dependent upon available nitrogen.

Nitrogen in manure is primarily organic N (slow release) with some inorganic (fast release) nitrate-N. Plants take up nutrients in inorganic forms. Organic material needs to decompose to allow for mineralization of nutrients to inorganic forms that are then available to plants. Plant available N is influenced by source, timing, soil conditions and temperatures. Crops grown for silage or greenfeed respond well to manure application to increase nitrogen levels. Legumes (such as alfalfa) can fix their own N and especially benefit from applications of P, which manure also provides.

In plants, phosphorus (P) plays a key role in complex energy transformations, photosynthesis, and is necessary for building proteins and other compounds. Seed, fruit and flower production is impacted by P. Phosphorus is involved with energy storage and transfer, vigorous root development, maturity, nodule formation and nitrogen fixation, and other essential functions in the plant. A P deficiency can have devastating impacts on crop quality and yield. P is a key nutrient in forage stand establishment.

Potassium (K) is essential for water regulation and stand longevity. It impacts rapid regrowth rate, nitrogen fixation, photosynthesis, efficient water use within plants, drought tolerance, suppression of invasive weeds and grass, and improved winter hardiness. Deficiencies can result in poor root systems, weak stalks or stems, slow growth and winter kill of perennials such as alfalfa and grasses.

Sulphur (S) is essential for chlorophyll production and for protein metabolism. Required for nitrogen fixation by legumes, deficiencies in legumes and forages can result in shorter plants with yellowing leaves. In western provinces, deficiency is becoming more common, with S being the third most limiting soil nutrient in forage crop production3.

Calcium (Ca) is an important component of cell walls, giving stability and structure. It also helps protect plants from heat stress and certain diseases which impair weak cell walls.

Magnesium (Mg), a key component of chlorophyll, plays a role in photosynthesis, nutrient uptake control, sugar synthesis, starch translocation and nitrogen fixation in legume nodules.

Properties and Benefits of Manure

Cattle manure is a dilute fertilizer due to its high content of water and organic materials. Soil with higher organic matter has a larger nutrient reservoir, is less susceptible to compaction, erosion, and surface crusting, and has increased water infiltration (less run-off) and water holding capacity. Higher organic matter levels can help moderate soil temperature and pH levels, improve plant root growth, and maximize biological activity in the soil. Microorganisms that use organic matter as a food source promote aggregation of soil particles, which improve soil structure, resulting in better water holding capacity in sandy soils and improved drainage in heavy, clay soils. Sequestration of carbon that results from increased soil organic matter can help reduce greenhouse gases4.

Manure with straw and bedding is an excellent source of organic matter when added to the land. The proportion of organic carbon (C) to total nitrogen (N) of manure or organic material is referred to as the C:N ratio. Soil micro-organisms use N as a food source while they break down carbon containing material. Then, the soil microbes die and decompose. Microbial N is returned to the soil and becomes available to the plants. The ratio of C to N determines how long it takes to complete this process. When there is not enough nitrogen in the organic material to break down the carbon, micro-organisms utilize nitrogen from the soil instead. C:N ratios higher than 25 to 30:1 can result in a temporary nitrogen deficiency of a crop that relies on soil nitrogen.

Estimates of N available to plants in the manure will vary depending on the composition of the manure and environmental conditions, however an average of 12 pounds of N in a ton (2,000 pounds) of beef cattle manure has been reported5. Ammonium and nitrate (inorganic) in manures are immediately available to plants. While approximately 25% of organic nitrogen in solid manure from livestock pens is estimated to be available to the crop in the year of application, manure that contains large amounts of straw or wood-chip bedding may only have a maximum of 10% to 20% of available N in the year of application6. In the second and third year following application, organic nitrogen continues to be mineralized, and can release up to 12% and 5% respectively7. Depending on composition and application rate, supplementation with commercial mineral fertilizer N may be necessary in the first couple years of manure application to ensure an adequate supply of N to plants.

|

Soil microbes break down organic material over several years, releasing nitrogen that is available for uptake by plants. |

Many interrelated factors impact nutrient levels in manure. Well-designed feeding and grazing systems combined with manure and nutrient management strategies can optimize efficiencies. Applying manure or nutrients beyond plant requirements wastes time and money. It can also impact the environment if over-applied nutrients leach into water bodies. Cattle are not able to utilize 100% of the nutrients that they consume. While highly variable depending on the animal, ruminants retain approximately 25% of consumed nitrogen, 35% phosphorus and 12% potassium8. Excess nutrients will be excreted through urine and feces. Reducing feed losses, improving digestibility, and feeding animals according to their requirements will help to avoid oversupplying nutrients, which may pass through the cattle onto the land.

Soil testing is an excellent way to avoid over-application of fertilizer. All plants, including forages, perennial legumes such as alfalfa, or annual crops such as barley have different nutrient requirements. When these plants are removed through grazing or harvest, considerable amounts of nutrients are also removed. As their yields increase, more nutrients are removed. For example, a corn silage crop can remove about 4.3 pounds of phosphorus per ton (2,000 pounds) of silage (35% dry matter)9. Each ton of alfalfa hay can remove 15 pounds of phosphorus. Application of manure can help to replace the nutrients that are removed. Using manure analysis together with soil tests to calculate the recommended rates will reduce the risk of over-application of certain nutrients.

Manure Storage, Treatment and Handling

In a cow-calf operation where cattle are often fed in pens for a portion of the year, pens are generally cleaned at least annually to remove accumulated manure and bedding. While backgrounders and feedlots have enforced protocols to manage and store manure, general guidelines apply to all producers who are handling and storing manure. Though specifics vary, examples from several provinces recommend:

- avoid short term stockpiles on sandy soils, rock quarries, or gravel pits

- use a concrete pad if possible, to prevent nutrient leaching into soil and groundwater

- have runoff containment, such as a lagoon

- ensure that stored manure areas are at least 60 metres from drilled water wells, 400 metres from municipal wells and 120 metres from all other wells, streams, rivers, lakes, and ponds

- the slope of the land where manure is stockpiled must not be greater than 3% to avoid overland runoff

- keep winter feeding sites and corrals at least 30 metres from bodies of water.

Treatment of stored manure can include stockpiling, composting, drying, and less commonly, separation and filtering. These methods reduce moisture content, which reduces volume and odour. Stockpiling (no treatment), composting and drying are the most common treatment strategies in beef cattle operations10.

Stockpiling manure generally involves pushing the manure, straw, bedding and residual feed out of the pens and into a large pile to sit for some time. This is a passive system since the manure will be placed in a storage area, such as at the edge of a field or in a designated storage site and left undisturbed. Microbial activity will occur, but the pile will become anaerobic without any further handling of the pile. Losses of N will occur with exposure to the atmosphere. Stockpiled manure is best in tall piles (rather than wide) or in windrows with a sloped surface to shed precipitation. This helps reduce loss of N and K as water moves through the pile. Stockpiles stored under a tarp or a shelter can retain up to 85% of N and K compared to outdoor piles that may retain only 75% of the N11.

Properties of stockpiled manure will vary based on the location in the stockpile:

- conditions are more anaerobic (lack oxygen) in the middle/bottom of the pile and more aerobic (have more oxygen) near the top

- warmer temperatures (after the initial set up of the stockpile) are found in the middle and bottom locations compared to outer/top locations

- the outer layers are drier than the middle and bottom core due to less evaporation

- more rapid decomposition (losses of carbon and nitrogen) occurs in the top/outer locations as the microbial community is more active.

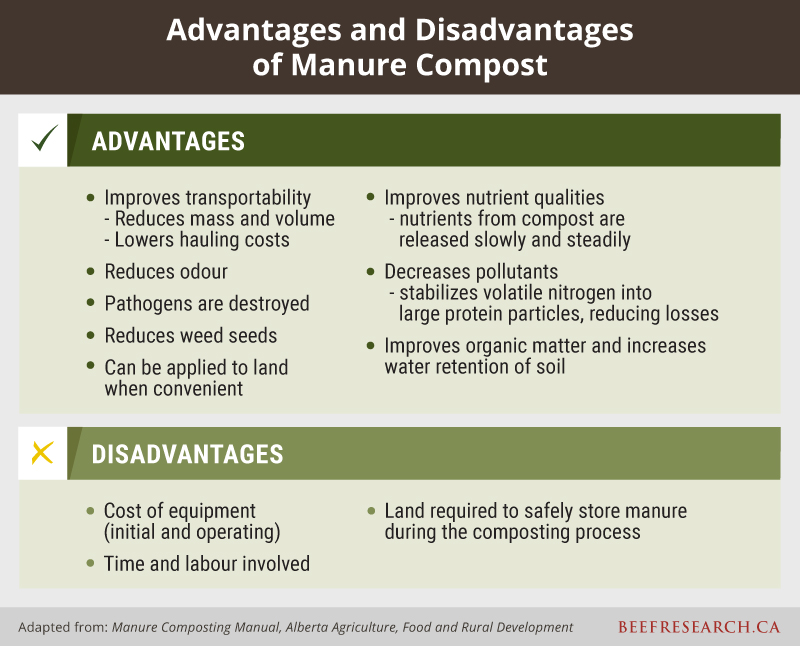

Composting is an active management treatment that encourages aerobic conditions to accelerate the breakdown of organic matter in the manure pile. Microorganisms consume oxygen while feeding on the organic matter, generating water vapour, heat and carbon dioxide. As the microbes digest the organic material the manure heats, often over 65 degrees Celsius. This heating can kill weed seeds, parasites and bacteria which cause plant diseases. While there are costs (fuel, labour, time) involved in turning the manure pile to begin the composting process, turning reduces volume and weight. Hauling costs can be reduced with as little as one turning. True composting relies on five or six turnings over three to six months with a period of curing. In the curing phase microbial activity slows down and composted manure approaches ambient air temperature.

Composting is an active management treatment that encourages aerobic conditions to accelerate the breakdown of organic matter in the manure pile. Microorganisms consume oxygen while feeding on the organic matter, generating water vapour, heat and carbon dioxide. As the microbes digest the organic material the manure heats, often over 65 degrees Celsius. This heating can kill weed seeds, parasites and bacteria which cause plant diseases. While there are costs (fuel, labour, time) involved in turning the manure pile to begin the composting process, turning reduces volume and weight. Hauling costs can be reduced with as little as one turning. True composting relies on five or six turnings over three to six months with a period of curing. In the curing phase microbial activity slows down and composted manure approaches ambient air temperature.

Moisture levels and aeration are important to monitor during composting. If the manure becomes too wet, over 60% of the nutrients may be leached, porosity is reduced, odours are produced, and decomposition is reduced. When moisture content drops below 40%, microorganism activity is reduced. Too much aeration cools and dries the material, reducing decomposition, and in high N mixtures ammonia volatilization and N loss can occur. While some nutrients can be lost during composting, reducing the volume of manure can also concentrate the nutrients in the compost relative to fresh manure. Research at Agriculture and Agri-Food Canada Lethbridge compared fresh and composted manure and found that composted manure retained 56% more N, 84% more P, 91% more zinc, and 76% more copper12.

Use the “squeeze test” to check for moisture levels. If water can be squeezed out, the manure is too wet. If it doesn't form a ball, it’s too dry.

This manure sample is too dry. When squeezed it does not form a ball. Photo credit T. Carter.

Several different methods of composting can be used such as creating piles or windrows of manure. Rows are commonly 10 to 12 feet (3 to 3.5 metres) wide and 4 to 6 feet (1.5 to 1.8 metres) high. Turning the pile or windrows with a front-end loader increases oxygen to facilitate the decomposition of the organic matter.

Producers often clean pens in the fall prior to moving weaned calves in for winter feeding. Fall composting allows the pile to decompose through the winter. While microbial activity is generally slower during cold temperatures, fall and winter composting can also reduce the risk of leaching and nutrient loss, avoiding run-off caused by heavy rains that may occur during summer composting. After the curing period, the composted manure will be ready for analysis and field application in the spring prior to seeding.

Drying, filtering and separating manure are less common treatment strategies in cow/calf operations. Innovative opportunities exist to develop treatment methods that can produce energy or other by-products such as bedding or fibre products.

Aerobic digestion of manure and the resulting biogas has been used effectively in some European countries, and the technology has recently been used to build Canada’s largest biogas plant in Lethbridge, Alberta. This plant will process over 100,000 tonnes of raw material including 50% liquid manure and commercial organic waste, producing 2.8 megawatts of power, which is enough for 2,800 homes13. While the capital cost of these innovative systems is prohibitive for smaller operations, advances in technology and products continues with a focus on protecting and preserving the environment.

Regulations

Regulations regarding manure storage and application are established and enforced at a provincial level. The parameters vary for each province and are based on factors such as stocking density and number of animals. As an example, in Alberta, the Natural Resources Conservation Board oversees the Agricultural Operations Practices Act which provides information about manure management. In Ontario, the Nutrient Management Act addresses the storage and application of manure.

Regulations may change with increasing focus on proper manure management. Information can be found through local extension and ministry of agriculture or environment offices to determine which regulations apply to each region. In addition to fact sheets outlining best management practices (BMPs), most provinces publish a manure management guide, available in hard copy or digitally. Contact local offices and organizations to learn about provincial regulations and manure management guidelines, and to ensure compliance.

Provincial Guidelines/Regulations

- Newfoundland and Labrador: Environmental Guidelines for Livestock Producers

- Prince Edward Island: Agricultural Waste Management

- Nova Scotia: Environmental Regulations Handbook for Nova Scotia Agriculture

- New Brunswick: Nutrient Management

- Quebec: Agricultural Operations Regulation, Environment Quality Act

- Ontario: Nutrient Management Act, 2002

- Manitoba: Restrictions on Winter Application of Nutrients

- Saskatchewan: Regulation of Intensive Livestock Operations in Saskatchewan

- Alberta: Manure management guidelines and legislation

- British Columbia: Code Of Practice For Agricultural Environmental Management

Manure Application

Manure is a valuable, yet challenging soil fertilizer. It is not a uniform product; it is heterogenous and variable, with many components such as straw, bedding and by-products of the animal’s diet. This can create challenges in management, utilization, and application as a soil amendment. Manure is typically pH neutral (7.0) to alkaline; however, once applied to the soil, the decomposition process may temporarily acidify the soil14. Manure contains soluble salts which can harm seeds or growing plants if too much is applied, and if drainage is poor. Stockpiled or composted manure contains fewer soluble salts, as they are leached out with time and exposure to precipitation.

Feed source and manure processing are two important sources of variability. Feed source will determine the amount of nutrients excreted through urine and feces. For example, dried distillers’ grains with solubles (DDGS) usually have significantly higher N and P content compared to conventional feed grains. As a result, manure produced from cattle fed DDGS was also found to be higher in N and P concentration and would need to be managed accordingly15. Recent research on cattle fed wheat or corn DDGS compared fresh and composted manure. Researchers found that compared to fresh manure, the composted manure maintained higher concentrations of N and P and had higher soil residual P levels compared to the fresh manure.

Application rates should be chosen based on nutrient requirements of the soil and crop to be grown, nutrient composition of manure, and the application method16. Higher rates of manure may be applied once every two years or three years to reduce time spent in the field but may increase the risk of nutrient loss in the year of application.

|

Using manure to supply N at recommended levels for crops will usually apply more P than required, which will increase soil P levels. |

Application of manure to meet nitrogen requirements adds a significant amount of phosphorus to the soil. For example, if the phosphorus content of manure being applied was 0.5% P, then 20,000 kg of manure applied to one hectare of land would also add 100 kg of P/ha (20,000 kg x .005 = 100 kg). Since most plants require N:P in a ratio of about 8:1 and cattle manure is higher in phosphorus than nitrogen, application of cattle manure as the sole source intended to meet a crop N requirement will typically add more P than the crop can use. Consequently, over time, the excess P will accumulate in the soil where it is susceptible to overland movement with water (surface runoff) and possible entry into water bodies. All soils have a maximum amount of P that it can adsorb (plant available P binds to soil particles making it immobile and less available to plants). As soils reach P saturation levels, losses to the environment through runoff and leaching increase. Phosphorus that enters bodies of water can create algal blooms and degrade water quality as it speeds up eutrophication (increased mineral and organic levels cause algal growth in water, which reduces dissolved oxygen levels).

Solid cattle manure is often applied to cropland in the form of surface broadcasting with a spreader, usually followed by an incorporation operation. Research has recently been conducted in western Canada on injecting solid cattle manure in bands17. Although enhanced nutrient recovery was sometimes observed from in-soil versus surface placement of the solid cattle manure, the benefits were relatively limited. However, in-soil placement was noted to have a large and significant benefit on reducing odours, with an average reduction of 37% noted18. Variable effects of in-soil placement on N and P exported in runoff have also been noted.

Solid cattle manure is often applied to cropland in the form of surface broadcasting with a spreader, usually followed by an incorporation operation. Research has recently been conducted in western Canada on injecting solid cattle manure in bands17. Although enhanced nutrient recovery was sometimes observed from in-soil versus surface placement of the solid cattle manure, the benefits were relatively limited. However, in-soil placement was noted to have a large and significant benefit on reducing odours, with an average reduction of 37% noted18. Variable effects of in-soil placement on N and P exported in runoff have also been noted.

While different methods of application include solid or liquid spreaders, liquid injectors and irrigated systems, most beef cattle operations store solid manure and apply it with a solid spreader. Using soil and manure analysis, together with a calibrated spreader to apply composted manure at a rate to target crop yield goals, provides more accurate nutrient application and can reduce risk of over or under application.

Timing of application is important to reduce odours and potential runoff. While most provinces have guidelines for spring, summer and fall application, others have strict regulations that are enforced with fines. For example, Manitoba has strict winter spreading regulations that prohibits manure spreading between November 10 and April 10. Quebec requires that manure spreading occurs prior to October 1 and after March 31. Ontario also prohibits spreading manure on frozen ground, or ground with snow cover. Ensuring responsible management of manure protects water sources and the environment. Some provinces also regulate how quickly manure must be incorporated into the soil. In Alberta for example, manure applied to cultivated land must be incorporated within 48 hours of application. This reduces odours, potential run-off, and nutrient loss due to volatilization. High temperatures, moist soils followed by dry conditions, and high soil pH increase these losses.

The following video, featuring Dr. Jeff Schoenau, Saskatchewan Ministry of Agriculture Soil Nutrient Management Chair in the College of Agriculture and Bioresources, University of Saskatchewan, provides tips on analyzing and applying manure at appropriate rates.

The 2001 Farm Environmental Management Survey collected data nationally on manure management on Canadian beef, dairy and hog farms. Most manure was applied to the land during fall (43.6%) and spring (29.9%) months. However, over half (53.3%) of beef cattle manure was left on the surface or incorporated into the soil after more than a week. Ideally, manure would be incorporated sooner to reduce odour, volatilization and runoff19. According to the 2016 Census of Agriculture, manure, either solid or liquid, was applied on just under a total of seven million acres across the country, with the largest percentage of those acres in Quebec (30.2%), Ontario (26.4%) and Alberta (17.3%)20. The 2017 Farm Management Survey reported that 76% of beef cattle operations broadcast solid manure on field crops and incorporated it into the soil. Manure is also used on pastureland with 37% of 2017 respondents using it as a management tool2. The format of the surveys and the questions asked of beef cattle producers in the Farm Management Survey changed from 2001 to 2017, making some comparisons of certain data more challenging.

Manure Management Plans

Opportunities exist for beef cattle operations to consider and develop manure management plans (MMPs). These contain records for each field including soil test results, nutrient requirements for the desired crops, yields, crop rotations, and usage and application rate of manure and/or commercial fertilizers. Less than 14% of beef farms surveyed in 2001 had developed an MMP. By 2011, 23.8% of farms surveyed in the Census of Agriculture had adopted a nutrient or manure management plan21. Part of a MMP includes reviewing and implementing beneficial management practices (BMPs) based on regional conditions to reduce environmental risks or realize environmental benefits. These BMPs are designed to protect groundwater and surface water, reduce runoff, and minimize nutrient losses and odour emissions.

Some factors to consider when creating a manure management plan:

- conduct soil tests to determine soil nutrient content

- analyze the manure to determine manure nutrient content

- establish a target yield to determine crop nutrient requirements

- calculate the manure application rate (think about the 4Rs - Right fertilizer source, Right place, Right rate, Right time)

- calibrate field equipment

- keep detailed records

- apply when temperatures are conducive to incorporate manure (do not apply to frozen ground)

- use direct injection or incorporate manure into soil following application to retain nutrients in the soil, reduce runoff, and minimize odours

- maintain a setback from water bodies and a buffer to filter nutrients according to regional regulations

- ensure adequate manure storage to contain all manure produced to avoid application on frozen ground

- ensure that manure storage is in an area with low slope to avoid runoff

- locate corrals, feeding sites and manure storage away from drainage areas and surface water bodies

- consider moving winter feeding sites, such as bale grazing, to a new location each year, including use of portable wind breaks to encourage animal movement and uniform manure distribution around the site.

Production Systems Impact Manure Management Strategies

Shifts in management practices have resulted in greater numbers of cows and calves being fed on pasture, rather than in pens. Producers have implemented strategies to reduce machinery usage and extend grazing into fall and winter by feeding stockpiled forages, cover crops, swath grazing, or bale feeding. Grazing management systems that utilize frequent rotations can improve nutrient utilization in pastures as cattle deposit urine and manure across the pasture. This has reduced the amount of manure collected in pens and increased the amount directly deposited onto pastures. The 2016 Census of Agriculture revealed that this shift is more pronounced in the western provinces and less common in Ontario and Quebec.

More than half of the approximately 634,000 tonnes of manure nitrogen produced by beef cattle in Canada annually is deposited directly on pasture. Producers can make efforts to manage nutrients from cattle manure and forage fertilization to reduce their environmental impact and improve their bottom line. The blog, What Happens when Manure Hits the Field, discusses nutrient cycling in forage ecosystems, and features a webinar by Shabtai Bittman, PhD, a researcher with Agriculture and Agri-Food Canada.

Feeding and overwintering cows directly in the field has been shown to increase overall nitrogen retention in the soil-plant system compared to hauling manure out of drylot pens and broadcasting on grass pasture22. This is because more of the nitrogen contained in cattle urine is retained when deposited directly in the field versus in a pen. This can significantly lower costs to producers for manure storage, hauling, and application. However, it limits the ability to apply composted or stockpiled manure to specific fields, crops, or forages to fertilize for a target yield.

Cattle swath grazing. Photo credit: T. Carter

When designing winter grazing sites, consider the implications of manure distribution. While vegetative buffers and live groundcover reduce leaching in summer and fall, these strategies are less effective in winter when the ground is frozen and plant material is not actively growing. Most run-off on these sites occurs as a result of snowmelt when the ground is still frozen. Greater risk of run-off occurs when manure is applied to sloped ground or areas with a shallow water table and little groundcover. Locating winter feeding sites with a setback from water bodies can minimize run-off, helping to protect these water sources. The following Wintering Site Assessment and Design Tool provides valuable tips and suggestions to reduce the environmental impact of winter feeding sites.

As the environmental impact of livestock on landscapes continues to be under scrutiny, producers are improving grazing and nutrient management strategies. Many have adopted BMPs outlined in the Verified Beef Production Plus program or completed provincial environmental farm plans. Corrals and winter feeding sites are being located in areas that reduce nutrient loss from manure that could negatively impact water bodies or other areas of the environment.

Soil sampling, manure analysis and good record keeping will assist producers in making decisions about application rates and manure management. A manure management plan will provide documentation that can help with planning and year-over-year comparisons, as well as demonstrating adherence to environmental guidelines.

Economics and Cost-Benefit

Strategies and BMPs to minimize environmental impact and improve storage, treatment, and application of manure can increase the value of this product. The bulky nature of manure, especially prior to composting, can be a limiting factor due to the costs to haul it to fields. In 2006, an Alberta study estimated that beef feedlot manure could be hauled economically between 4.99 and 18.82 km depending upon the nutrient content and the phosphorus availability23.

The cost of storing, treating, and applying manure must be measured against the benefits that it provides. While pen cleaning and manure spreading is often viewed as an expense to an operation, the short and long-term benefits of improving soil quality and organic matter, reduced costs of synthetic fertilizer, and adding nutrients must be taken into account. The benefits of manure can be longer lasting than commercial fertilizer due to the improvements it can make to soil structure and water infiltration. It can be difficult to factor these continued benefits into a cost/benefit analysis of manure application. Several provinces have created calculators to estimate the various costs and benefits of manure application.

Conclusion

Manure is a valuable by-product of cattle operations. Nutrients critical to healthy plant growth, such as nitrogen, phosphorus and potassium are present in manure. It also contains organic matter that contributes to soil quality and productivity. The bulky, heterogenous nature of manure can create some storage, treatment, and application challenges. Careful analysis of the soil and manure nutrient levels will help to create a nutrient management plan that supplies the plants with the desired nutrients, without oversupplying, which can waste money and potentially damage the environment. With increased focus on protecting water sources, preserving biodiversity, and maintaining sustainable operations, producers are encouraged to explore regional BMPs and create manure management plans to better utilize this renewable resource and ensure compliance with all provincial and federal regulations.

Definitions

Adsorption: the chemical binding of plant available phosphorous to soil particles, making it unavailable to plants.

Eutrophication: when increased mineral and organic levels cause algal growth in water, reducing dissolved oxygen levels.

Leaching: the removal of dissolved nutrients such as nitrogen (N) and phosphorous (P) from the soil by vertical water movement. N moves easily with water, so the rate of leaching depends on soil drainage, rainfall, amount already present in soil and plant uptake.

Nitrification: the process by which microorganisms convert ammonium to nitrate to obtain energy. Nitrate is the most plant available form of nitrogen but is susceptible to leaching.

Nitrogen Fixation: the conversion of atmospheric nitrogen (N) to a plant available form. Legumes like alfalfa, bird’s foot trefoil and clover can fix their own nitrogen. In grass-legume stands with at least 25% legume, no additional N is needed. These plants have a high demand for phosphorus to support nodule formation and function.

Nitrogen Immobilization: occurs when soil organisms take up ammonium, making nitrogen unavailable to plants. Manure with high levels of straw and bedding (carbon:nitrogen ratio greater than 40:1) increase biological activity and result in nitrogen immobilization.

Nitrogen Mineralization: when microbes decompose organic nitrogen from manure, organic matter, or crop residue, resulting in inorganic nitrogen that is available to plants.

Nitrogen Volatilization: loss of nitrogen (N) through the conversion of ammonium to ammonia gas. Manure that is not incorporated into the soil has higher losses of N through volatilization. Hot, windy conditions increase these losses.

Runoff: is a major cause of phosphorous (P) loss from farms and ranches. Dissolved P from manure and fertilizers can be carried into water bodies, impacting water quality and potentially increasing algae blooms.

This topic was last revised on February 19, 2021 at 8:37 AM.

View Web Page

View Web Page View PDF

View PDF