Hormones & Other Growth Promotants in Beef Production

Growth promotants are among the many sophisticated tools used by feedlots and other producers to raise more pounds of beef, more rapidly, using less feed, with decreased environmental impact, while maintaining high standards of animal health, carcass quality and food safety. Growth promotants include ionophores, growth implants, and beta-agonists. Health Canada’s Veterinary Drug Directorate oversees the regulatory approval and oversight of these products in Canada’s beef industry, and the Canadian Food Inspection Agency conducts random tissue tests for drug residues to ensure prescribed dosages and withdrawal times are adhered to.

On This Page

- Key Points

- Why are they used?

- Categories of Growth Promotants

- Regulation of Growth Promotants

- Frequently Asked Questions Regarding Growth Promotants

- How do Growth Promotants Improve Growth Rate and Feed Efficiency?

- What are maximum residue levels (MRLs)?

- Can consumers be confident Canadian beef is safe from drug residues?

- What would happen if a licensed veterinary product had an adverse effect (Pharmacovigilance)?

- What would happen if the Canadian beef industry stopped using growth promotants?

- What are the Alternatives to Growth Promotants?

Key Points

|

Why are They Used?

| Analysis indicates that production costs would be at least 10% higher if producers did not use implants, ionophores or beta agonists. |

Growth promotants are valuable tools for both cow-calf producers and cattle feeders. A study1 led by Dr. Ira Mandell of the University of Guelph reported that overall average daily gain was 21% higher and feed efficiency was 23% better for grain finished cattle given both implants and ionophores compared to control cattle. Economists John Lawrence and Maro Ibarburu at Iowa State University reported2 that average daily gain increased when ionophores (8% in stocker cattle and 3% in finishing feedlot cattle), implants (13% in stockers and 16% in finishers), and beta-agonists (16% in finishers) were used. Feed efficiency in finishers improved when ionophores (4% better), implants (9%) and beta-agonists (13%) were used. Their analysis indicated that feedlot production costs would be at least 10% higher if producers chose not to or were unable to use implants, ionophores or beta agonists. Research on the environmental and economic consequences of removing growth promotants is currently underway in Canada.

Canfax data indicate that between 1977 and 2007, Canada slaughtered 20% fewer cattle but produced 11% more beef. When fed cattle exports are included in this calculation, Canada produced 10% more cattle, but produced 39% more beef. Growth promotants played a significant role in improving these production efficiencies.

Canfax data indicate that between 1977 and 2007, Canada slaughtered 20% fewer cattle but produced 11% more beef. When fed cattle exports are included in this calculation, Canada produced 10% more cattle, but produced 39% more beef. Growth promotants played a significant role in improving these production efficiencies.

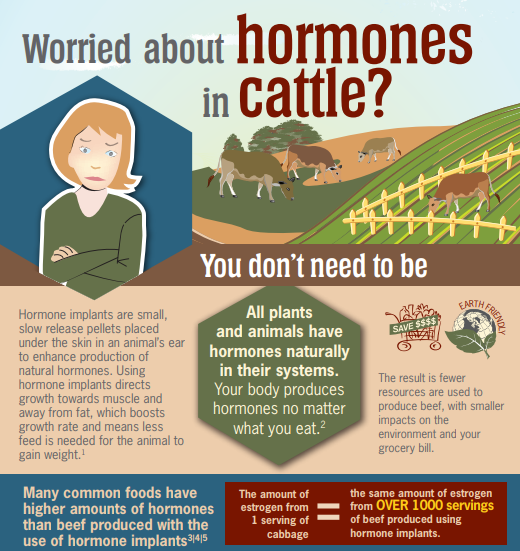

Questions About Hormone Use in Beef ProductionAdapted from Alberta Beef Producers, Worried About Hormones What are hormone implants?

Are hormone implants safe and regulated in Canada?

Are there hormones in the beef I eat?

|

Categories of Growth Promotants

Hormones

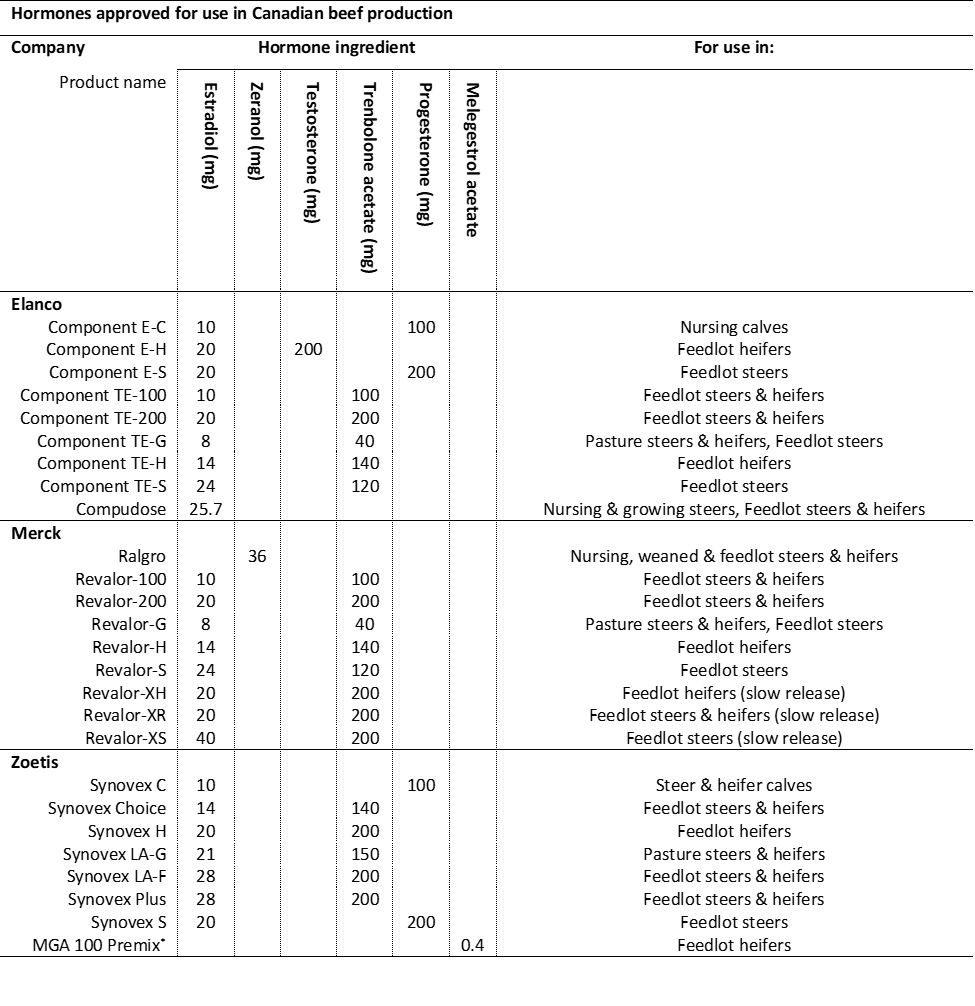

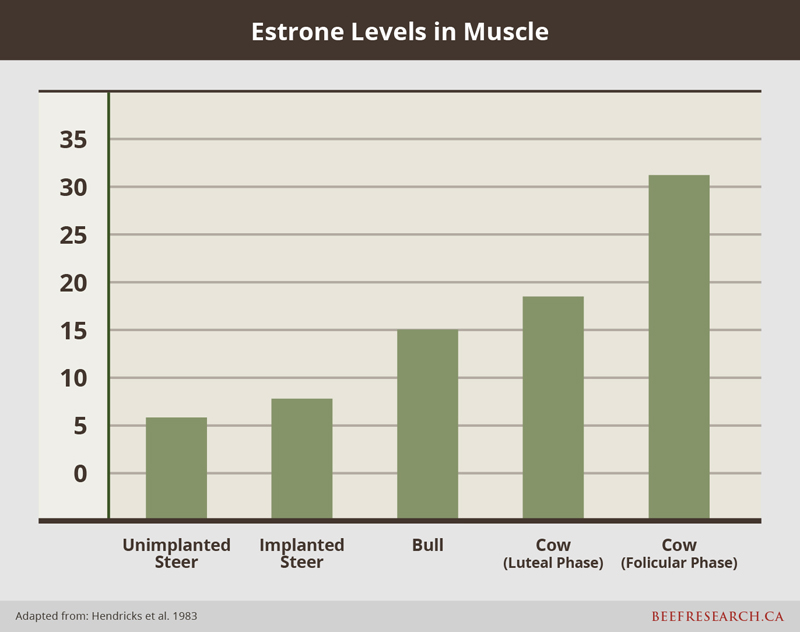

Hormone implants have been approved for use in cattle since the 1950s, with the most recent (implants containing trenbolone acetate) approved in the mid-1980s. Implants partially replace the hormones that steers lack as a result of castration. Bulls are castrated to eliminate the reproductive hormones that contribute to aggression, reduce animal welfare concerns, avoid unplanned mating, and minimize meat quality problems. However, these hormones also allow bulls to grow more rapidly, efficiently, and develop more lean muscle than steers or heifers. Hormone implants, delivered through a pellet under the skin of a steer or heifer’s ear, replace some of these natural reproductive hormones in steers (or augment them in heifers). This improves the growth rate, feed efficiency and carcass composition of steers and heifers, while mitigating the behavioral and meat quality problems we want to avoid in bulls.

Calf implants can significantly increase weaning weights, particularly in heifers. For example3, heifers implanted with zeranol (Ralgro) at 60 days of age weighed 6% (over 30 pounds) more at weaning than unimplanted heifers.

Use in feeder cattle: The use of growth implant hormones allows a 13% increase in ADG in grass cattle, and a 16% increase in ADG in finisher feedlot cattle2.

Hormones used in beef cattle contain one or a combination of three naturally occurring reproductive hormones (or synthetic versions that have similar structure and function):

| Natural hormone | Synthetic version |

| Estradiol | Zeranol |

| Progesterone | Melengestrol acetate |

| Testosterone | Trenbolone acetate |

*This is not an implant; this is a diet additive, fed at 0.4mg per head per day to control estrus

The implant gradually releases the hormone over time, so the animal is only exposed to a minute amount of hormone each day. For example, the 200mg of TBA and 40mg of estradiol in a Revalor-XS implant are slowly released over a 200-day period.

Caution is warranted when implanting potential breeding stock. Bull calves intended for breeding should never be implanted. Do not implant heifers intended for breeding more than once. Heifers3 implanted with Ralgro at 60d of age had heavier weaning weights compared to unimplanted heifers, with no negative impact on age at puberty, pregnancy rate, calving percentage, calving difficulty or calf birth weight. However, significantly delayed puberty, failure to conceive, and abortions have been observed4 when heifers were implanted more often.

One hormone, melegestrol acetate (MGA), is sometimes used as a feed additive to suppress estrous cycles in feedlot heifers. MGA can improve growth rate and feed efficiency because heifers that aren’t cycling expend less feed energy pursuing or avoiding riding behavior. MGA must be managed very carefully to reduce the risk of dark cutting.

Ionophores

|

As with all technology, appropriate and optimal use of growth promotant products can improve animal performance and utilization of feed resources, while improper use may result in no benefit and lower carcass value. |

Ionophores were introduced in the mid-1970s and are fed to cattle to prevent diseases like coccidiosis, acidosis and bloat, in addition to improved weight gain and feed efficiency. Ionophores improve feed efficiency by acting on rumen microbes. Rumen microbes convert the fiber and starch in forage and grain into volatile fatty acids (primarily acetate, propionate and butyrate) and ammonia that can be absorbed into the bloodstream to provide energy and protein to the animal. Ionophores act on the rumen bacteria to increase the proportion of propionate produced, which is more energetically favorable than acetate. However, some rumen bacteria produce methane instead of acetate, propionate or butyrate. Methane contains energy but cannot be absorbed by the animal, so it is belched out and wasted. Ionophores contribute to reduced methane production, because the proportion of methane produced decreases when the proportion of propionate increases.

| Ionophores approved for use in Canada | |

| Ionophore | Product name (company) |

| Lasalocid sodium | Avatec (Zoetis) |

| Bovatec (Zoetis) | |

| Salinomycin sodium | Coxistac (Phibro) |

| Posistac (Phibro) | |

| Monensin sodium | Coban (Elanco) |

| Monensin (Bio Agi Mix) | |

| Rumensin (Elanco) | |

Ionophores are antimicrobials categorized as 'Low Importance' in human medicine, meaning they are not used to treat bacterial infections in humans. Ionophores have a very different mode of action than medically important antibiotics, and antimicrobial resistance to ionophores does not result in co- or cross-resistance to medically important antibiotics. Ionophores are often erroneously included in discussions about antimicrobial use in livestock and potential links to antimicrobial resistance in humans.

Beta-agonists

Beta adrenergic agonists are the newest class of growth promotants, commercially available in Canada since 2004. These feed additives are neither antimicrobials nor hormones. Human asthma medications are also beta-agonists.

‘Beta adrenergic agonist’ is a complicated name that describes what these products do. ‘Adrenergic’ means ‘resembling adrenaline.’ ‘Agonist’ (the opposite of antagonist) means that ‘it works in a similar manner.’ The ‘beta’ refers to the specific receptor that it binds to on the muscle cell surface. So, a beta-adrenergic agonist is a substance that binds to a beta receptor on the muscle, and acts sort of like adrenaline. Adrenaline diverts blood flow from the digestive organs towards the muscle during the ‘fight or flight’ response. Similarly, beta-agonists re-direct nutrients so that more growth occurs in muscle tissue than in internal organs.

The beta-agonists approved for use in beef cattle (ractopamine and zilpaterol) increase protein deposition (muscle growth), growth rate, feed efficiency, and carcass leanness. Some beta-agonists also reduce protein turnover (reduce muscle breakdown), resulting in increased dressing percentage. Beta-agonists are fed at the end of the feeding period, when muscle growth is slowing, fat deposition is speeding up, and feed efficiency is dropping off.

As with aggressive implants, beta-agonists must be managed appropriately, on the right class of cattle at the right time in order to avoid negative consequences on carcass quality (especially reduced marbling levels). The benefit of feeding beta-agonists can be lost if the product is fed for too long, or if the delay between product withdrawal and slaughter is too long.

Some have expressed concerns about the use of beta-agonists in livestock. A 2014 observational study5 compared health records from nearly a million US feedlot cattle, some which had received beta-agonists and others which hadn’t. The risk of death was slightly higher in cattle that had been fed a beta-agonist, although no unique cause of death was noted. The main causes of death in the cattle fed a beta-agonist - (digestive and respiratory illness) are also the most frequent cause of death in feedlot cattle that aren’t fed beta-agonists. Other concerns attributed to beta-agonists, including a perceived increased risk of lameness, fatigue and respiratory distress have since been attributed6 to improper handling of large cattle in hot weather.

In spite of rigorous pre-approval safety testing that is conducted before pharmaceutical products are approved for use in Canada, some importing nations have a zero-tolerance policy for certain kinds of beta-agonists. This can become an issue in trade negotiations. These concerns are likely related to clenbuterol7, a beta-agonist that is not approved for use in cattle, is metabolized differently, can leave residues in meat, and which has been linked to health concerns in humans. Clenbuterol has never been approved for use in cattle in North America but has been used illegally in some countries that do not allow the use of growth promotants. In fact, a person would have to eat more than 13.5 kg (30 pounds) of beef per day, or over 2.25 kg (5 pounds) of liver per day, from cattle administered an approved beta-agonist in order to get the effect of one “puff” of asthma medication.

| Beta-agonists approved for use in Canada | |

| Beta-agonist | Product name (company) |

| Ractopamine hydrochloride | Actogain (Zoetis) |

| Optaflexx (Elanco) | |

| Ractopamine (Bio Agri Mix) | |

| Zilpaterol hydrochloride | Zilmax (Merck) |

Regulation of Growth Promotants

Approval

In Canada, veterinary drugs are regulated by the Food and Drugs Act and Regulations. All veterinary drugs go through a Health Canada approval process before they are licensed for use. Health Canada is one of 187 government members of the Codex Alimentarius Commission. The Codex was established by the Food and Agriculture Organization (FAO) of the United Nations and the World Health Organization (WHO) to develop harmonized international food standards, guidelines, and codes of practice to protect the health of consumers and ensure fair food trade practices.

The Health Canada Veterinary Drug Directorate (VDD) evaluates and monitors the safety, quality and effectiveness, and sets standards for the use of veterinary drugs to ensure that, when used according to label directions, they are safe for both animals and humans.

Label and veterinary directions indicate proper administration doses and routes, as well as pre-slaughter withdrawal times that ensure that the product has been metabolized by the animal before it is slaughtered.

For a more detailed explanation of the veterinary drug approval process in Canada, visit

http://www.beefresearch.ca/files/pdf/canadas-veterinary-drug-approval-process.pdf

Withdrawal times

Label and veterinary directions indicate proper administration doses and routes for veterinary products, as well as pre-slaughter withdrawal times. These ensure that the product has been metabolized by the animal before the meat is harvested. Most drugs are completely metabolized during the prescribed minimum number of days between the last administration of the drug and slaughter, and therefore leave no residue.

Inspection and Residue Testing

All animals and carcasses are subjected to pre- and post-slaughter inspections to look for signs of ill health. Random samples of carcass tissues and organs are tested for residues from antimicrobials, growth promotants, and other contaminants.

Frequently Asked Questions Regarding Growth Promotants

How do Growth Promotants Improve Growth Rate and Feed Efficiency?

Implants encourage protein deposition while leaving fat deposition unaffected. This improves weight gain and feed conversion efficiency. Fat deposition requires more than twice as much feed energy as protein deposition does. In addition to this, muscle tissue contains around 70% water, while fat contains around 10% water. This means that for every ten pounds of muscle gained, about three pounds comes from dry feed and seven pounds comes from water. This ratio is reversed for fat growth (roughly nine pounds from dry feed and one pound from water). The net result is that increasing muscle growth more than fat growth improves growth rates and reduces the amount of feed required per pound of body weight gained.

Meat Quality

Negative impacts on carcass quality (maturity, marbling score, tenderness, and possibly color), can occur when aggressive growth promotant regimes are used at the wrong time or on the wrong types of cattle. Cattle feeders are very careful to match the growth technologies used to the type of cattle they are used on, simply because carcass pricing is heavily influenced by marbling score (quality grade). Any reduction in quality grade could negatively affect feeding margins significantly.

Similarly, implants and beta-agonists may negatively impact tenderness, juiciness and flavor of beef when used at the wrong time or in the wrong class of cattle. However, differences reported between beef from cattle raised with or without growth promotants are typically small, are more commonly detected by trained taste panelists than by regular consumers and can be effectively mitigated when beef is aged for 21 days8 (the approximate average time beef is aged in Canada it reaches the retail shelf9).

Video presentation on implants and carcass quality by Dr. Sandi Parr, feedlot nutritional and production consultant:

What are maximum residue levels (MRLs)?

There is a zero tolerance for residues of many veterinary drugs in beef allowed for human consumption. Some veterinary products have standardized maximum residue levels (MRLs) established by Health Canada. MRLs are set far below the amount that could pose a human health concern when ingested daily over a lifetime.

Learn how Canadian MRLs are determined in point #6 here: http://www.beefresearch.ca/files/pdf/canadas-veterinary-drug-approval-process.pdf

Can consumers be confident Canadian beef is safe from drug residues?

The CFIA randomly samples the food supply for potential contamination. It is extremely rare that unacceptable residue levels are detected. Foods exceeding the limit are further analyzed by CFIA/Health Canada to determine if a product seizure or recall is necessary. Test results that raise concerns are a very rare occurrence, but regular testing ensures the safety of Canadian beef. The CFIA’s 2015-16 National Chemical Residue Monitoring Program found no residues in Canadian or imported beef that exceeded allowable limits.

The following webinar titled "Hormone use in beef cattle: facts, fears, fantasies" discusses hormone use in beef cattle.

What would happen if a licensed veterinary product had an adverse effect (Pharmacovigilance)?

Cattle producers, veterinarians, pharmaceutical companies and Health Canada’s VDD work together to identify, report and investigate potential cases of adverse drug reactions.

To learn more about how the VDD monitors livestock drugs on an ongoing basis even after they have been registered, approved and licensed in Canada, visit http://www.beefresearch.ca/files/pdf/pharmacovigilance.pdf

Human health – oral bioavailability

Growth promotant safety has been reviewed by many experts and agencies, including Health Canada, the World Health Organization and the Food and Agriculture Organization of the United Nations. All have concluded that hormones can be used safely in beef production. The levels found in food products, such as beef, are too low to be of risk to human health.

To put these levels into perspective, consider the levels of estrogens that occur naturally in all plants and animals, including humans. This table shows that a person would have to eat 225 tonnes of hamburger every day from cattle administered growth hormones before he or she would be exposed to as much estrogen as the average women produces daily.

| Quantity | Source | Nanograms of estrogen |

| 75g | Beef without hormone implants | 1.1 |

| 75g | Beef with hormone implants | 1.9 |

| 75g | Chicken | 2.1 |

| 75g | Pork | 2.5 |

| 355ml | Beer | 15 |

| 355ml | Milk | 51 |

| 75g | Cabbage | 2025 |

| 1 Tbsp | Soybean oil | 28, 370 |

| 1 | Birth control pill | 20,000 – 50,000 |

| Per day | Adult male | 136,000 |

| Per day | Adult woman | 480,000 |

| Per day | Pregnant woman | 19,000,000 |

Testosterone-containing implants are similar; there is a safety factor of several thousand-fold based on the assumption that people consume the equivalent of 6 to 7 servings of beef per day, which greatly exceeds the average Canadian’s beef consumption (less than one 75g serving of beef daily).

The way growth hormones are used in cattle is not the same as steroid abuse in sports. For example, the 200mg of trenbolone acetate in a Revalor-XS implant are released over a 200-day period, so the steer receives about 1mg of trenbolone acetate per day. In contrast, a bodybuilder injecting this hormone to exaggerate their muscle development would inject 100mg trenbolone acetate daily as competition nears.

Steroid hormones have very low oral availability (about 10%)10. That means that hormones that are eaten, regardless of whether they’re from beef, tofu, or any other food, are not absorbed from the digestive tract or enter the bloodstream at high enough levels to have a physiological effect. That’s why medically therapeutic hormones are given by injection rather than orally.

Download: Worried about hormones in cattle? Developed by the Alberta Beef Producers. (PDF)

Environmental benefits

A 2012 study11 published in the Journal of Animal Science quantified how the growth promotant technologies used in North America (including ionophores, implants and beta-agonists) have allowed the beef industry to produce the same amount of beef from fewer cattle in less time. This has led to environmental benefits. If we were to remove these technologies from our production system, we would need 10% more cattle, 10% more land, and 10% more feed to produce the same amount of beef. Doing this would also require 7% more fuel and fertilizer. The reduced feed efficiency and longer days to finish would also mean that the cattle would produce 10% more manure and greenhouse gas in the process. To learn more about how Canadian beef production is becoming more efficient, visit http://www.beefresearch.ca/blog/producing-beef-with-lower-greenhouse-gas-emissions-and-using-fewer-resources/

These technologies increase the amount of beef that each animal can produce and have allowed North American beef producers to continue to provide consumers with a safe, high quality product in the face of rising feed and land prices while reducing environmental impacts. As with all technology, the appropriate and optimal use of growth promotants can improve animal performance and resource utilization, while improper use results in no benefit and reduced carcass value. Feedlots, nutritionists and veterinary experts base their decisions to use these products on the results of large-scale commercial field trials, past experience, the type of cattle being fed, marketing practices and packer specifications.

What would happen if the Canadian beef industry stopped using growth promotants?

In the absence of growth promotants, cattle would be less efficient, require more feed, and have a higher environmental impact per serving of beef. These factors would increase retail prices considerably, making Canadian beef unaffordable for many families and uncompetitive in the world market.

Because the proper use of growth promotant technologies does not pose any scientifically valid food safety concerns, discontinuing their use would have clear negative consequences for the Canadian beef industry and the environment with no obvious benefit for human health.

What are the Alternatives to Growth Promotants?

Genetics: Genetic selection for improved growth rate, feed efficiency and carcass composition has been suggested as an alternative to the use of growth promotants in the beef industry. One challenge with implementing this suggestion is that there are significant genetic trade-offs between the traits that different sectors of the beef industry rely on. There are two main production stages in the beef cattle industry. The viability of the ranch, farm or cow-calf stage relies very heavily on a high level of reproductive performance on an extensive, forage-based environment. In contrast, the viability of the feeding stage depends on efficient growth and productivity under more controlled conditions and with a higher quality diet. From a genetic perspective, optimal reproduction under a low-input environment difficult to reconcile with rapid, efficient feedlot performance. Reproductive and growth traits are negatively genetically correlated. As one improves, the other declines. It is difficult or impossible to develop an optimal genetic package that works adequately for both the cow-calf and feedlot sectors. The cow herd needs to be able to survive and reproduce in a natural environment in which they’re raised with minimal supplemental feed, while their offspring need to be able to grow rapidly and efficiently in the feedlot. The beef industry breeds for reproductive performance under demanding ranch conditions and manages for growth performance under controlled feedlot conditions. Growth promotants provide the same performance, economic and environmental benefits in cattle regardless of their genetic makeup. The beef industry’s use of growth promotants enables the efficient production of high-quality beef from a genetic base developed to thrive and reproduce in a demanding, forage-based environment.

Hormone-free beef: Some cow-calf producers may feel that unimplanted calves are worth more in the marketplace. This may be true in some circumstances. However, a 2015 study12 found that implant status had no effect on the price received for 2,749,406 calves sold in 92 US video auctions between 2010 and 2013. Interestingly, the percent of calves implanted varied significantly among different regions of the country. This is also true in Canada. The proportion of Canadian cow-calf producers who implanted their calves in 2017 was 0.24% in Atlantic Canada, 2.4% in Ontario, and 26.5% in Western Canada. At present, this reluctance to market implanted cattle and beef is not as pervasive at the feedlot, packer or retail levels. Canada’s 2013-18 National Beef Quality Audit found that very few beef roasts and steaks sold in Canadian retail stores carried label claims noting “organic” status (1.1% of roasts and 0.9% of steaks), “hormone-free” (a claim that is technically not permitted, but found on 0.5% of roasts and 0.3% of steaks), or “no hormones added” (2.7% of roasts and 4.2% of steaks).

There are marketing opportunities for producers who feel that the potential premium for cattle and beef raised without growth promotants is sufficient to offset the performance benefits of growth promotants. For example, some Canadian retail and foodservice companies, as well as the European market, do not accept the use of growth promotants. Information for Canadian cattle producers interested in these markets is available here.

As shown in the table above, all foods of plant and animal origin contain hormones. However, not all countries (notably the European Union) allow the importation of beef produced from implanted cattle. Interestingly, some of these countries raise bulls instead, and so require higher levels of management (smaller pen sizes, stronger facilities, modified transportation and slaughterhouse practices) to accommodate the challenges associated with feeding bulls.

In summary, growth promotants may be the single most important technology the beef industry uses. They are safe for animals and consumers, allow us to produce more beef, reduce our impact on the environment and help maintains the profitability of our industry for our producers.

Ironically, beef from intact bulls almost certainly contains higher levels of natural hormones than would ever be encountered in beef from implanted North American cattle.

Feedback

Feedback and questions on the content of this page are welcome. Please e-mail us.

This topic was last revised on June 18, 2020 at 1:33 AM.