Feed Grains for Beef Cattle

Cereals such as corn and wheat are grown across North America for use as human food, for livestock feed and for industrial purposes such as ethanol. From a livestock perspective, cereals are utilized either as whole plant forage (i.e. silage, green feed) or as feed grains.

Cereals such as corn and wheat are grown across North America for use as human food, for livestock feed and for industrial purposes such as ethanol. From a livestock perspective, cereals are utilized either as whole plant forage (i.e. silage, green feed) or as feed grains.

Cereal grains are actually the seeds of grasses (i.e. barley, oat, wheat and corn) which develop as the plant matures over the growing season. During this development, the seed fills with starch and associated protein. Increasing the concentration of starch at maturity is the plant’s method of storing energy for germination and early seedling development. While an important aspect of plant growth and reproduction, this concentration of nutrients in the mature seed head is also important for agricultural and industrial purposes.

The cattle feeding sector relies on cereal grains as concentrated sources of energy, particularly in finishing rations where cereals make up to 90% of the ration dry matter. This heavy reliance on cereals as an energy source is due in part to the fact that the cost per unit of dietary energy is typically less for cereal grains than for any other readily available feed source. As well, cereal grains make an important contribution to the protein needs of growing and finishing cattle.

High nutritional value, competitive pricing and ready supply all combine to make cereal grains attractive feed sources for the cattle feeding sector. However, not all cereal grains are equal, particularly from a nutrition perspective. Differences exist in dietary energy as well as crude protein content. As well, differences in kernel structure such as the presence or absence of a hull, impact nutrient content and availability and thus the need for processing.

On this Page

- Key Points

- Canadian Cereal Grain Production, Classification and Uses

- Nutritive Value of Barley, Corn and Wheat

- Processing Requirements for Cereal Grains fed to Cattle

- Common Methods to Process Cereal Grains

- Evaluating the Effectiveness of Your Grain Processing Program

- Digestive Characteristics of Starch from Barley, Wheat and Corn

- Managing Cattle on High Grain Rations

- Purchasing Grain for the Feedlot

Key Points

|

Canadian Cereal Grain Production, Classification and Uses

Barley Grain

Barley has long been an important crop for Canadian farmers, particularly those in western Canada where the majority (> 95%) of seeded barley acreage is located. Canadian barley production ranged from 7.9 to 10.4 million metric tonnes from 2015 to 2019 with 10.4 million tonnes in 20191.

Barley has long been an important crop for Canadian farmers, particularly those in western Canada where the majority (> 95%) of seeded barley acreage is located. Canadian barley production ranged from 7.9 to 10.4 million metric tonnes from 2015 to 2019 with 10.4 million tonnes in 20191.

Barley is grown primarily for malt, feed and food purposes; however, the majority of growers target the malt market as it typically brings the greatest gross returns. Barley that fails to meet malt specifications (i.e. protein less than 13%; free of mycotoxins; high germination %) is typically marketed as feed. This market is by far the largest outlet for Canadian barley. Comparatively speaking, only a small proportion of barley grown in Canada is used for human consumption.

|

Barley can be classified as either two- or six-row with this classification relating to differences in the physical structure of the cereal head. Two-row barley varieties typically produce larger, plumper seeds. Barley varieties are also classified on the presence or absence of a hull. Hulless varieties are used primarily for human food, although when priced appropriately, they can be used as livestock feed. The term hulless is actually a misnomer, as these varieties have a loosely attached hull that falls off during harvesting as opposed to a tightly attached hull present on normal varieties. |

|

Beneath the hull and seed coat of the kernel is the endosperm and germ. The endosperm contains most of the starch, which is embedded with protein. The starch and protein of barley grain is rapidly and extensively degraded in the rumen, particularly for processed barley grain2.

Wheat Grain

Similar to barley production, wheat is grown across Canada, with the majority of seeded acreage in western Canada. Over the period 2015 to 2019, Canadian wheat production averaged 31 million tonnes with 32. 4 million tonnes in 20191. While there are numerous classes of wheat grown across Canada, the most important are the spring and durum classes. In 2019, spring wheat accounted for 79% of total Canadian wheat production, durum accounted for 15% with the remainder primarily winter wheat classes1. As opposed to barley, the vast majority of Canadian wheat production is destined for human consumption. Wheat typically enters the feed market when there are issues with quality, such as fusarium or mildew contamination or issues with sprouting.

Similar to barley production, wheat is grown across Canada, with the majority of seeded acreage in western Canada. Over the period 2015 to 2019, Canadian wheat production averaged 31 million tonnes with 32. 4 million tonnes in 20191. While there are numerous classes of wheat grown across Canada, the most important are the spring and durum classes. In 2019, spring wheat accounted for 79% of total Canadian wheat production, durum accounted for 15% with the remainder primarily winter wheat classes1. As opposed to barley, the vast majority of Canadian wheat production is destined for human consumption. Wheat typically enters the feed market when there are issues with quality, such as fusarium or mildew contamination or issues with sprouting.

Wheat kernels lack a protective hull; however, they possess a seed coat that provides protection from the environment. Like barley, the endosperm contains most of the starch and protein, both of which are rapidly degraded in the rumen. While wheat can be fed as the sole grain in growing and finishing rations, many nutritionists restrict inclusion levels to 40 to 50% of the concentrate due to concerns with rumen acidosis. Questions arise regarding the feeding value of durum versus spring wheat. Research from NDSU that compared durum with hard red spring wheat indicated that cattle fed durum-based finishing rations consumed less feed, had poorer gains and feed conversions that those fed the hard red spring variety. The poor performance was attributed to durum’s gluten content and its influence on palatability of the processed grain3.

Corn Grain

Traditionally, Canadian corn production was located in central and eastern Canada, primarily in Ontario, Quebec and Manitoba. Of the 13.4 million tonnes produced in 2019, approximately 12 million tonnes were grown in Ontario and Quebec1. However, with the development of short season corn hybrids, this picture is changing with increased acreage in Saskatchewan and Alberta, particularly of silage varieties.

Traditionally, Canadian corn production was located in central and eastern Canada, primarily in Ontario, Quebec and Manitoba. Of the 13.4 million tonnes produced in 2019, approximately 12 million tonnes were grown in Ontario and Quebec1. However, with the development of short season corn hybrids, this picture is changing with increased acreage in Saskatchewan and Alberta, particularly of silage varieties.

Corn is a remarkably versatile grain with uses in food, feed and industrial markets. Feed corn is widely used in cattle, swine and poultry rations. Corn use for human consumption includes sweet corn, corn flour, corn meal, and corn grits, while major industrial uses include ethanol production and value-added products such as sweeteners and corn oil.

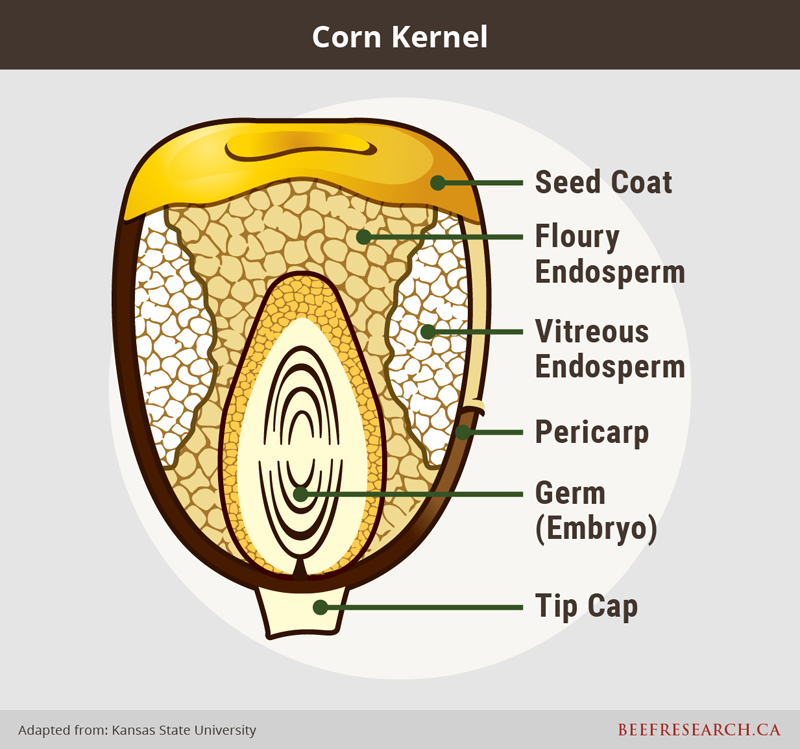

Corn can be classified as dent or flint types. Dent corn is the principle type grown for livestock feed. Dent corn is typically yellow in color. The interior of the kernel is characterized by an endosperm that is soft and floury on the inside and harder and more dense (vitreous) on the outside4, 5. The endosperm contains most of the starch, which in the case of dent varieties is relatively digestible, particularly that found in the inner floury endosperm. The harder vitreous endosperm also contains protein that forms a protective matrix with the densely packed starch granules5. A seed coat or pericarp surrounds the endosperm. At maturity, the cap of the dent kernel is dented, hence the classification.

Flint corn has a harder, more vitreous endosperm that consists of tightly packed starch cells with protein. This difference in endosperm morphology leads to reduced starch and protein digestibility when compared to dent varieties.

Oat Grain

Oat production in Canada ranged from 3.2 to 4.2 million tonnes over the period from 2015 to 2019. Oat grain is used primarily for livestock feed and human food. Oat varieties grown in Canada include those selected for general purpose, milling, and feed purposes. Similar to barley, most of these varieties possess an outer hull that comprises 25% of the kernel weight and contributes to the lower test weight of oat relative to other cereal grains. The endosperm and germ contains the majority of the starch, protein and oil content of the kernel. Similar to that from barley and wheat, exposed starch is rapidly and extensively degraded in the rumen of cattle.

Nutritive Value of Barley, Corn and Wheat Grain for Cattle

Feed grains are characterized nutritionally as excellent sources of energy and intermediate sources of protein and individual minerals such phosphorus and magnesium. Differences in nutrient value between grain types, to a large degree reflect differences in kernel structure as discussed above.

Relative Value of Barley, Corn and Wheat as Energy Sources for Cattle

In terms of energy density, cereal grains typically follow the order corn > wheat > barley > oat. This is evident from Table 1 which shows that oat grain has a total digestible nutrient (TDN) content of 77%, barley 84%, wheat 87% and corn 88% (DM basis). The relative low energy content of oat and barley grain is due in part to the presence of an outer hull with high fibre (i.e. acid and neutral) content, as well as a lower starch content relative to wheat and corn (Table 1). In contrast, corn with its relatively low fibre and high starch and fat content has the highest energy content of the four grains listed.

In addition to higher starch levels, the starch in corn grain is not as digestible in the rumen or in the small intestine, as that from oat, barley or wheat 2. This is due to inherent differences in kernel structure discussed above, as well as to the protective nature of the protein in the endosperm of the corn kernel. These differences between the major cereal grains in terms of fibre and starch content are not only important in terms of chemical composition but also influence the nature and degree of processing required to optimize feeding value.

| Table 1: Dry matter, fibre, starch and fat content and energy values of common cereal grains used in beef rations. | ||||

| Nutrient (DM basis) | Barley | Oat | Wheat | Corn |

| Dry Matter % | 89.0 | 89.0 | 89.0 | 88.0 |

| Acid Detergent Fibre % | 7.0 | 13.0 | 4.0 | 4.0 |

| Neutral Detergent Fibre % | 18.0 | 27.0 | 12.0 | 10.0 |

| Fat % | 2.8 | 6.2 | 1.9 | 3.8 |

| Energy | ||||

| Total Digestible Nutrients % | 84.0 | 77.0 | 87.0 | 88.0 |

| Digestible Energy Mcal kg | 3.71 | 3.38 | 3.83 | 3.86 |

| Net Energy maintenance Mcal kg | 2.06 | 1.85 | 2.15 | 2.17 |

| Net Energy gain Mcal kg | 1.40 | 1.22 | 1.47 | 1.49 |

Adapted from: Nutrient Requirements of Beef Cattle 8th edition

Relative Value of Barley, Corn and Wheat as Protein Sources for Cattle

|

Rumen degradable protein is feed protein or non-protein nitrogen (i.e. urea) that is degraded in the rumen and available to rumen bacteria for protein synthesis. Rumen undegradable protein “bypasses” the rumen and is potentially available for digestion in the small intestine of the animal. |

Table 2 lists the crude protein and rumen degradable protein content of the four grain types. In terms of crude protein (CP) content, wheat typically is superior to barley and oat, which in turn are superior to corn grain. In addition to the amount of crude protein, differences exist in the rumen degradability of the protein. Corn protein, as with starch, is slowly degraded in the rumen and as a result, corn has a higher proportion of rumen bypass protein than oat, wheat or barley.

| Table 2: Crude protein content and degradability of common cereal grains | ||||

| Nutrient (DM basis) | Barley | Oat | Wheat | Corn |

| Crude Protein | 12.8 | 12.6 | 13.8 | 8.8 |

| Rumen Degradable Protein | 49.4 | 43.5 | 64.2 | 34.6 |

| Rumen Undegradable Protein | 50.8 | 56.5 | 35.6 | 65.3 |

Adapted from: Nutrient Requirements of Beef Cattle 8th edition

Differences between grain types in protein content and degradability can influence the amount and form of supplemental protein provided to cattle. For example, it is common practice in many growing and finishing programs to supplement protein, particularly if forage quality is poor. However, in order to achieve the same target CP content in the ration, the amount of supplement required will typically be greater in corn-based diets than that required in wheat- or barley-based diets. As corn has a higher by-pass protein content, it is a good practice when supplementing protein to corn-based diets to provide a supplement high in rumen degradable protein, in order to promote rumen fermentation and bacterial protein synthesis.

Mineral Content of Barley, Wheat and Corn

With respect to the macro minerals, it is safe to say that all cereal grains are low in calcium (Table 3), particularly in relation to the calcium requirement of growing and finishing cattle, which can range from 0.45 to 0.75% of the ration dry matter6. As a result, calcium supplementation is required in almost all grain-feeding situations other than where legumes make up a significant proportion of the forage program. This is particularly true in finishing programs where cereal grains make up a high percentage of the ration dry matter. In contrast, cereal grains are relatively good sources of phosphorus and intermediate sources of magnesium, sulfur and potassium.

As evident from Table 3, cereals are variable sources of trace minerals, with wheat and barley having higher levels of copper, zinc and manganese than corn grain. However, it is important to realize that other than very young calves, cattle do not effectively absorb many of the trace minerals found in natural feedstuffs6. To ensure adequate trace mineral intake, an appropriate mineral supplementation program is required.

| Table 3: Mineral content of common cereal grains used in beef cattle rations | |||

| Nutrient (DM basis) | Barley | Wheat | Corn |

| Calcium % | 0.08 | 0.08 | 0.03 |

| Phosphorus % | 0.38 | 0.36 | 0.29 |

| Magnesium % | 0.13 | 0.13 | 0.11 |

| Potassium % | 0.53 | 0.43 | 0.37 |

| Sulfur % | 0.14 | 0.15 | 0.11 |

| Copper ppm | 6.10 | 5.40 | 2.60 |

| Manganese ppm | 21.9 | 43.0 | 7.80 |

| Zinc ppm | 30.6 | 29.3 | 20.5 |

Adapted from: Nutrient Requirements of Beef Cattle 8th edition

Processing Requirements for Cereal Grains Fed to Cattle

The negative influence of the seed coat on overall digestibility is the primary reason we need to process cereal grains prior to feeding. Differences in the nature of the seed coat of the various cereal grains will dictate the extent of processing required.

As discussed above, barley kernels possess an outer hull as well as an inner seed coat that serves a protective role. This hull is not easily broken by chewing and forms a significant barrier to the fermentation activities of rumen bacteria. Since the bacteria cannot get access to the starch and protein in the intact kernel, digestibility of whole barley is poor, relative to processed barley. Numerous studies have shown that dry rolled barley is 10 to 30% more digestible than whole barley, with the greatest impact on starch digestibility8.

Oat grain also has a hull and inner seed coat but in contrast to barley, cattle more effectively chew the oat kernel, particularly calves under a year of age. A review of the benefits of processing oat grain for cattle concluded that rolling would only improve dry matter digestibility by 5 to 10% for growing cattle8. A recent oat breeding innovation is the development of a high fat groat (kernel), low lignin hull oat released as CDC SO1 oat. This oat has been shown to have similar feeding value to barley grain in backgrounding diets without the need for processing8. CDC Nasser oat with similar traits has also recently been released.

In contrast, wheat and corn kernels do not have an outer hull; however, they do have a protective seed coat or pericarp. In wheat, this seed coat is resistant to chewing and to the activities of the rumen bacteria. As with barley, feeding unprocessed wheat to cattle can result in reductions in dry matter digestibility ranging from 10 to 25%, depending on the nature of the feeding program8. The seed coat of the corn kernel is not as resistant as that in wheat and is relatively easily broken by the chewing activity of the animal. This allows rumen bacteria to access the interior of the kernel and allows fermentation to occur. As a result, ruminal starch digestibility of whole corn is similar to that of dry rolled corn with both forms of corn having similar energy values (Table 4)3, 7. Not surprisingly, the performance of cattle fed whole corn is similar that of cattle fed dry rolled corn10, 11. Despite satisfactory results with feeding whole corn, research has shown that processing such as steam rolling or flaking can increase starch digestibility both ruminally and post-ruminally4,5 and lead to higher energy values for the more extensively processed grain6 (Table 4).

Common Methods to Process Cereal Grains

The goal of any method of grain processing is to break open the outer hull and/or seed coat in order to expose the interior of the kernel to bacterial fermentation. However, optimal processing is not always easy too achieve. If grain is under-processed, digestibility is less than optimal, while over-processed grain can have an excess of fines or very small grain particles that can lead to digestive upsets and issues with cattle going off feed.

Grinding

Grinding cereals such as barley involves the use of a hammermill with a rotating series of hammers that physically grinds grain kernels until they reach a particle size that allows them to pass through a screen. Particle size is controlled by the openings on the screen and the speed of the hammers12. Hammermills do an excellent job of processing and minimizing the proportion of whole kernels. In fact, often they do too good a job, resulting in processed grain with too high a level of fines. The resulting highly processed grain, particularly that from barley and wheat, is rapidly fermented in the rumen and can lead to digestive upsets and issues with cattle going off feed. To minimize the level of fines, appropriately sized screens must be used during the grinding process, selection of which will require trial and error on the operator’s part. Another issue is that relative to roller mills, grinders are typically not as efficient in terms of energy use12. For these reasons, hammermills are not widely used for processing grain, particularly in those operations that rely on barley and wheat as grain sources.

There are, however, situations where hammermills are used to process grain. For example, some manufacturers of forage processing equipment have incorporated on-board hammermills into the design of bale processors. This allows cattle to be fed a mixed hay/straw/grain ration under extensive / pasture conditions. In such situations, grain particle size is not as critical, as the level of grain feeding is generally low relative to a finishing operation.

Dry-rolling

|

Dry rolling is the most common method of processing oat, barley and wheat kernels in Canada and is also used with corn. Cattle can perform very effectively when fed dry-rolled grain. Surprisingly, there is little difference between cattle fed dry-rolled barley and those fed dry-rolled corn8, 12 with some recent studies indicating superior performance with dry rolled barley13. Failure of cattle fed dry-rolled corn to outperform those fed dry-rolled barley is due to the relatively poor ruminal and total tract digestibility of starch in corn grain compared to that of barley grain. |

|

Processing dry grain with a roller mill involves passing whole kernels through two rotating horizontal steel rolls. The intent is to crack or break the kernel into two or three pieces without having too high a level of fines. In most rollers, one roll is stationary, while the other is movable. This allows operators to vary the width of the gap between the two rolls and control particle size of the processed grain. The narrower the gap, the more extensive the processing. Rolls can be smooth or grooved. Smooth rolls compress the grain, while grooved rolls tend to tear or grind the grain12. The number of grooves can range from four to fifteen grooves per inch. The greater the number of grooves, the smaller the grain particles once rolled. The rolls may or may not be offset, a configuration that can help draw grain into the gap between the two rolls. As well, many rollers are equipped with a differential drive where one roll rotates at a faster speed than the other, an innovation that helps to reduce particle size through both compression and shearing action12.

Steam Flaking

Steam-flaking involves holding grain that has been soaked with moisture (tempered) in a steam chamber at atmospheric pressure and subjecting it to steam for a predetermined time and temperature (i.e. corn is typically held in a steam chest for 30 to 35 minutes at temperatures ranging from 95 to 105oC)5. The combination of steam, temperature and holding time causes the starch granules to absorb moisture and irreversibly swell, a process known as gelatinization, which results in an increase in starch digestibility4, 5. As well, there is disruption to the protein matrix in the vitreous endosperm of corn.

Steam rolling is a less intense form of steam processing corn. Grain is subject to a shorter residence time in the steam chest and rolled to a coarser, less dense flake4. The rolling process both compresses and shears the grain. This shearing activity is important as it further disrupts the protein matrix of the endosperm, enhancing starch digestibility5. Rolls are set to control both the density and thickness of the flaked grain. Typically, the lower the density and/or thinner the flake, the greater the impact on starch digestibility.

Steam flaking has primarily been used to process corn grain. Given the less digestible nature of starch within the corn kernel, this type of processing will increase corn net energy values compared to either dry-rolled or whole corn (Table 4). This increase in net energy is responsible for the improved performance of cattle fed steam-flaked corn relative to those fed whole or dry-rolled corn10.

| Table 4: Processing effects on relative energy value of corn grain | ||||

| Nutrient (DM basis) | WC | DR | HM | SF |

| Total digestible nutrients % | 88.0 | 87.6 | 90.4 | 95.0 |

| Digestible energy Mcal/kg | 3.87 | 3.86 | 3.98 | 4.19 |

| Net energy maintenance Mcal/kg | 2.18 | 2.17 | 2.25 | 2.38 |

| Net energy gain Mcal/kg | 1.45 | 1.49 | 1.56 | 1.67 |

Because the starch and protein content in processed barley and wheat kernels is already rapidly degraded in the rumen, responses to steam-flaking barley have been varied, ranging from relatively small increases in net energy content15, to little or no improvement in cattle performance15, 16. These results, as well as the increased cost of steam flaking has led most nutritionists to recommend dry rolling or temper rolling as the method of choice when processing barely or wheat for cattle.

Recent research at the University of Saskatchewan is challenging these assumptions. Studies on barley subjected to steam for as little as 5 minutes, has shown improvements in starch availability as reflected by reduced fecal starch levels as well as improved feed efficiency of cattle fed steam-flaked barley17. This research along with the potential for increased corn grain feeding, particularly in western Canada may result in an increase in the use of steam flaking technology to process grain for feedlot cattle.

High Moisture Grains

There are two common methods of feeding high moisture grains, including tempering or harvesting the grain at an elevated moisture level.

Tempering grain involves adding water to dry grain (at 12 to 14% moisture) to raise the moisture level to 18 to 20%. The wet grain is then held for a 12 to 24 hour period and rolled prior to feeding. Benefits include a reduction in fines and a more even roll. Performance benefits are variable and depend to some extend on grain type. With corn, tempering improved cattle performance over dry-rolled corn18, while little benefit was observed when tempered barley was fed to finishing bulls19.

High moisture grain (i.e. corn or barley) is harvested at a moisture content of 25 to 30%. Following harvest, the high moisture grain is processed through a roller mill and then ensiled in bunkers or bags. As with silage production, efficient packing to eliminate oxygen is critical for efficient fermentation20. Harvesting high moisture grain offers a variety of agronomic benefits to growers including reduced field losses, higher yields, increased harvest flexibility and no requirement for drying.

As with steam flaking, harvesting corn at 28 to 30% moisture has an impact on the nature and digestibility of the corn kernel. The starch content of high moisture corn is degraded faster and more extensively than that of dry-rolled corn4. As result, the net energy value of high moisture corn is similar to that of steam-flaked corn (Table 4).

Evaluating the Effectiveness of Your Grain Processing Program

Evaluation of the effectiveness of the grain processing program is a critical aspect of any feeding program. The goal is to ensure that the grain is processed appropriately to ensure maximum feed value. In the case of dry rolling, issues include over-processing resulting in too high a level of fines, which can lead to digestive upsets, and under-processing where there are too many whole kernels coming through the roller. In the latter case, these whole kernels likely pass right through the cattle. In the case of steam-flaked grain, failure to control flake thickness and density can lead to reduced starch digestion and reduced performance. The following are critical control points one can utilize to monitor the effectiveness of the grain-processing program.

Level of Fines

Fines are a particular concern when dry-rolling cereals. They represent over processed grain particles, a result of too narrow a gap between rolls or from processing very dry grain. The level of fines in dry-rolled grain can be evaluated by sieving a defined amount of processed grain (i.e. ½-litre cup) through a screen with defined openings (i.e. 1.0 to 1.4 mm) 19.

| The percentage of fines is calculated as the weight of the processed grain that falls through the screen expressed as a percentage of the original sample weight. |

|

Photo credit John McKinnon |

The ideal target level of fines in a sample of processed grain will vary from feedlot to feedlot depending on the aggressiveness of the grain milling operation. Commonly, a target of 5 to 7% fines with dry-rolled barley and 5% with wheat are necessary to ensure adequate processing. In addition to evaluating the level of fines, it is possible to evaluate the percentage of whole kernels coming through the roller. Ideally these are kept to a minimum (i.e. 5% or less), although variation in particle size can make this a difficult target to achieve19.

Processing Index (PI)

| The processing index is the ratio of the weight of a known volume of processed grain to that of the same volume of unprocessed grain, expressed as a percentage21. |

The greater the degree of processing, the lower the index. The optimal PI ratio will vary between nutritionists, as well as between feedlots and may change with the type of grain fed. For example, it is common when comparing across feedlots to see the PI index for dry-rolled barley range from 65 to 80%. The best application of the PI index is as an indicator of the aggressiveness of the feeding program. For example, a PI index of 65% or less can be considered aggressive, a PI ratio of 65 to 75% moderate and a ratio greater than 75% as non-aggressive. Producers falling into the aggressive category should have a heightened awareness of potential issues with acidosis and ensure that they practice superior feeding management. Those with a PI index of 80% or greater, should consider the potential for excessive fecal starch losses, which can contribute to poor feed conversions.

Flake Density

For steam flaked grain, the most common indicator used to evaluate the effectiveness of the flaking process is the density of the flakes. Research has shown that within limits, starch digestibility is negatively related to the density of the flakes. With corn, densities between 0.35 and 0.30 kg/L are common5. Limited research with barley suggests that a value close to 0.40 kg/L will optimize net energy content relative to dry rolled barley15, 17. The ideal method to optimize flake density is to measure fecal starch content of cattle fed flaked grain where the density is known. The goal is to identify the flake density that minimizes fecal starch content and then use it as a reference to monitor the effectiveness of the roller. Flake thickness can also be used as a monitoring tool. Generally, the thinner the flake, the greater the improvement in starch digestibility5.

Manure Content, Colour and Consistency

In addition to evaluating the processed grain coming through your roller mill, it is also is important to evaluate the nature and consistency of the manure excreted by cattle. The first thing to look for is the amount of whole grain in the manure. With dry-rolled grain, particularly barley, it would be a rare situation to find manure devoid of any whole kernels. However, with practice you can walk pens and evaluate the relative degree of whole grain in the manure. In cases where the number of whole kernels seem higher than normal, appropriate adjustments can be made to the roller. A more objective method is to have your nutritionist take samples for starch analysis. Fecal starch levels can range from less than 5% in cattle fed steam-flaked corn to greater than 20% in poorly rolled barley.

It is also important to visually monitor the consistency and color of the manure. Both traits reflect the nature of the diet fed to the cattle and can provide insights to cattle health as well as to the effectiveness of the feeding program. For example, blood in manure can indicate issues with mycotoxins, coccidiosis or hemorrhaging in the lower gut23. Cattle grazing fresh pasture will have manure that is dark green in color. Feces are generally loose due to high moisture content of the grass. Manure from cattle adapted to high grain diets is more of an olive-green to brown color and has a consistency that allows for a typical dome-shaped “pie”23. Feedlot cattle that experience digestive upsets such as sub-acute acidosis can exhibit a loose, fluid-like manure that flows over the pen surface with a color that can range from very dark to greyish.

Example of high grain diet with normal manure consistency. Photo credit John McKinnon.

Loose manure indicating digestive upset. Photo credit John McKinnon.

Digestive Characteristics of Starch from Barley, Wheat and Corn

Figure 1 illustrates the relative rates of ruminal starch degradability for cereal grains processed to varying degrees. Lowest rates are seen with whole grains such as barley, wheat and corn, while the fastest degradation rates are seen with processed oat, barley and wheat, regardless of processing method. With corn the rate of ruminal starch degradation increases with processing, as you move from whole corn to dry-rolled corn to steam-flaked corn to high moisture corn22.

Figure 1: Relative rate of ruminal starch digestion for cereal grains

This effect of processing cereals has two major effects. First, maximizing starch digestion is what processing is all about. The goal should be to achieve 95% or better starch utilization by the animal. However, cattle feeders need to exercise caution when feeding highly processed grain sources as rapid ruminal fermentation of starch can lead to excess acid production. This acid load stresses the ability of the animal to maintain a normal rumen pH and can lead to issues with rumen acidosis, particularly in cattle not accustomed to grain feeding. Symptoms can include issues with cattle going off-feed, loose watery manure, dehydration, and in worse case scenarios, death.

In practice, acidosis can be classified as acute, sub-acute and chronic forms of the disease. Symptoms generally reflect the severity and duration of the ruminal acid stress. In all cases, feeding management is at the heart of the issue. With acute acidosis, typically cattle that are naive to grain feeding (i.e. newly weaned calves) are fed the wrong ration by mistake, usually the finishing ration. These animals cannot handle the resulting rumen acid load, become dehydrated, appear listless and go off feed. In severe cases, death occurs 24 to 48 hours after over-consumption of the grain.

Sub-acute acidosis also results from mistakes in feeding management. Generally, the insult to the rumen is not as great as that seen with acute acidosis. Examples might include feeding wrong rations to an existing pen of cattle, missed feedings or over feeding a pen of hungry cattle. Symptoms are similar to acute acidosis but not as severe, and afflicted animals generally recover.

Chronic acidosis develops from mistakes in feeding management that are repeated over time. These include poor feed delivery and/or bunk management practices, excessive grain processing or any aspect of management that leads to variable intakes of high grain rations. Cattle go through cycles of high and low intakes that lead to repeated bouts of sub-acute acidosis. Not only is performance negatively impacted from issues related to the condition but associated issues such as laminitis and liver abscesses can further compound the health and performance of cattle.

Managing Cattle on High Grain Rations

Issues with acidosis whether acute or chronic are typically associated with poor feeding management. At the heart of the issue, is that in order to maintain normal rumen and digestive function, cattle and more specifically the rumen bacterial population requires adaptation to high-concentrate feeding. Grain adaptation is essentially the process of shifting the rumen bacterial population from one specializing in fermenting forages to one that specializes in fermenting grain. This shift needs to occur gradually and in steps, the number of which will depend on the nature of the feeding program.

Step-up Feeding Programs

While there are a range of feeding programs used to adapt cattle to high grain rations, most feedlots utilize a version of a step-up feeding program. These programs consists of a series of rations formulated to increase in energy density (i.e. grain level) as you move from one ration to another. Depending on the program, there can be up to five to eight rations that range from the starter through to the final finishing ration.

The starter ration is typically comprised of 30 to 40% concentrate (i.e. cereal grains), 55 to 65% forage and 3 to 5% supplement (dry matter (DM) basis). As you move from the starter ration, the ratio of concentrate to forage changes at each step such that the amount of concentrate increases by approximately 10% and the level of forage deceases by 10% (DM basis). If we look at the finishing ration, in most cases it will range from 80 to 90% grain, 7 to 15% forage and 3 to 5% supplement. Between the starter and finisher, there can be five to six steps, sequentially increasing in grain concentration. In the case of a backgrounding operation, the feeding program typically consists of the starter ration and anywhere from two to four rations that again increase in energy content by varying the grain to forage ratio.

Feed Bunk Management

Feed bunk management is the practice of ensuring that cattle are fed to meet performance expectations. Specific goals include feeding the correct ration, ensuring that cattle are fed the right amount of feed and taking steps to ensure that cattle remain healthy when fed high grain rations for extended periods.

Feed bunk management is the practice of ensuring that cattle are fed to meet performance expectations. Specific goals include feeding the correct ration, ensuring that cattle are fed the right amount of feed and taking steps to ensure that cattle remain healthy when fed high grain rations for extended periods.

Feeding the correct ration is a function of identifying performance expectations for the cattle being fed and providing a well-mixed ration that meets nutrient requirements for that class of cattle. Using a step-up feeding program with defined energy and protein concentrations at each step of the program will help facilitate feeding the correct ration, particularly when one is feeding a variety of pens that differ in frame, weight and performance expectations. A well-mixed ration includes accurate weighing of ingredients as specified by batch sheets or by the truck computer; following a specified order of ingredient inclusion where small volume ingredients are added towards the end of the load; and allowing for adequate mixing time.

Ensuring that the correct amount of feed is provided daily to each pen is perhaps the most difficult task associated with feeding management. Most feedlots keep cattle on full feed within defined limits. In other words, cattle are eating very close to appetite. With such a strategy, one will typically see the bunks empty for a defined period (i.e. two to four hours) over the course of a 24-hour period. Feeding in such a manner prevents cattle from over-eating, particularly on high grain rations.

Keeping cattle on high grain rations for extended periods without getting into issues with chronic acidosis is another challenge. Critical to success is the role of the ‘bunk reader’ whose job it is to determine how much feed is allotted per pen, when and how much to increase and when to change to higher grain rations. When increasing the amount fed, it is wise to provide defined increases over a specified number of days. Larger increases are provided early in the step-up program with more restricted increases at later stages. The goal is to minimize large day-to-day swings in feed intake.

In the case of transitioning to higher grain rations, moving cattle up a step-up program is the ideal method to follow. At each step of the program, give 3 to 4 days of feeding to allow the cattle to adjust to the higher level of grain. As well, when changing rations, avoid moving to a higher ration on the same day you increase the amount fed and transition to the higher grain ration during the afternoon feeding, if possible.

Other measures to ensure that cattle maintain relatively high levels of feed intake while on high grain rations include:

- multiple daily feedings

- consistent feeding times

- providing an initial cover of feed to cattle with slick bunks, particularly those on the finishing ration in order to minimize issues with over-eating

- recognizing and adjusting to weather induced changes in feeding behavior and

- distributing feed evenly over the entire bunk.

As well, ionophores can be fed to help minimize day-to-day variation in feed intake and to help control digestive disorders.

Purchasing Grain for the Feedlot

Many variables influence the relative nutritive value of different feed grains. In addition to differences between grain types there are also a number of factors that influence feeding value of any given grain type. The following are important considerations that feedlots use to assess economic value.

Moisture content: Feed grains are typically purchased at a moisture content of 14.5% or less. Higher moisture levels can lead to heating and mold growth, as well as potential bridging issues during storage. Grain with higher moisture levels (i.e. 15 to 17%) can be utilized, particularly during the winter if it is stored outside and used relatively quickly. When purchasing grain with higher moisture levels, it is important to adjust the purchase price based on the actual dry matter content of the grain.

|

Barley (48 lb bushel weight) at 14.5% moisture and priced at $4 per bushel is worth $184 per tonne as is, or $215 per tonne ($184 / 0.855) on a DM basis. At 16.5% moisture, this same barley has 2% less dry matter and is worth $180 ($184 * 0.98) per tonne. The dry matter value is, however, the same ($180 / 0.835 = $215). |

Test weight or bushel weight: The most common measurement used for purchasing grain is test weight or bushel weight.

Standard test weights (pounds per bushel)

|

From a feeding perspective, the concern generally is with lightweight grain and relates to inadequate starch filling of the kernels and thus a potential for reduced feeding value. While this is a valid concern, cattle typically perform very well when fed light test-weight grain, unless density falls below critical levels. For example, cattle fed light test-weight barley (i.e. < 48 lbs) will gain similarly to those fed normal test weight barley, although feed to gain ratios tend to rise as test weight drops. With very light test-weight barley (i.e. < 43 lbs); both gains and conversions are negatively impacted24. Similarly, cattle fed light test weight wheat (i.e. 55 lbs) or corn (i.e. 46 lbs) will perform equally as well as cattle fed normal test weight grains with minimal impact on feed conversions. Perhaps the greatest challenge one faces when feeding lightweight grain is ensuring adequate processing due to variation in kernel size.

Plumpness: This trait reflects grain uniformity and is positively associated with starch content of the kernel. Barley plumpness can be measured by using a set of # 6 (6/64 inch) and # 5 (5/64 inch) slotted screens to sieve the grain. Kernels remaining on top of the # 6 screen are classified as plump; those falling through to the #5 screen are classified as thin, with material falling to the pan classified as waste (i.e. dust, small weed seeds). Plumpness values in excess of 90% are desired from both a feed value and processing perspective.

Mycotoxins: When purchasing cereal grains, it is a good idea to have a screening program for potential mycotoxin contamination. Cereal grains as well as associated by-products such as dry distillers’ grains or grain screenings are potential sources of mycotoxins that can cause serious health issues if consumed by cattle. Mycotoxins are by-products of various species of fungus that develop on the plant during the growing season and in some cases on the grain during storage. The extent of contamination varies with grain type and with specific environmental factors that affect plant growth, particularly during the spring. Mycotoxins of concern result from ergot and fusarium contamination of cereals and aflatoxin contamination of stored corn grain. For a detailed discussion on the effects of mycotoxins on cattle visit the BCRC Mycotoxin topic page.

Conclusion

Cereal grains are used extensively by the Canadian beef industry, primarily as sources of energy. In terms of ranking, corn and wheat are superior energy sources for cattle, followed by barley and oat grain, respectively. Differences in energy content reflect differences in starch content and kernel structure, particularly the presence or absence of an outer hull. Oat grain can be successfully fed whole to growing cattle due to superior chewing ability relative to mature cattle. Barley and wheat require processing in order to optimize digestibility of starch and other nutrients with dry rolling the method of choice. Corn grain may be fed whole, dry-rolled or steam flaked or as high moisture grain with performance optimized with steam flaked and high moisture grain. With all cereals, rapid rumen fermentation of starch can predispose cattle to issues with rumen acidosis, making feed and bunk management critical components of the overall management program.

Feedback

Feedback and questions on the content of this page are welcome. Please e-mail us.

This topic was last revised on May 13, 2020 at 1:25 AM.

Photo credit Aaron Beattie

Photo credit Aaron Beattie Photo credit John McKinnon

Photo credit John McKinnon

View Web Page

View Web Page View PDF

View PDF